8 Wastes Of Lean Examples

8 Wastes Of Lean Mutomorro Overall, these 8 waste categories in lean methodology cover the vast majority of waste that you can experience either in a manufacturing environment or in daily life. as you have seen throughout this article, many of the 8 wastes are interconnected. Lean thinking aims to remove wastes from work processes. before diving into the 8 wastes, it is important to understand what waste is. waste is any action or step in a process that does not add value to the customer.

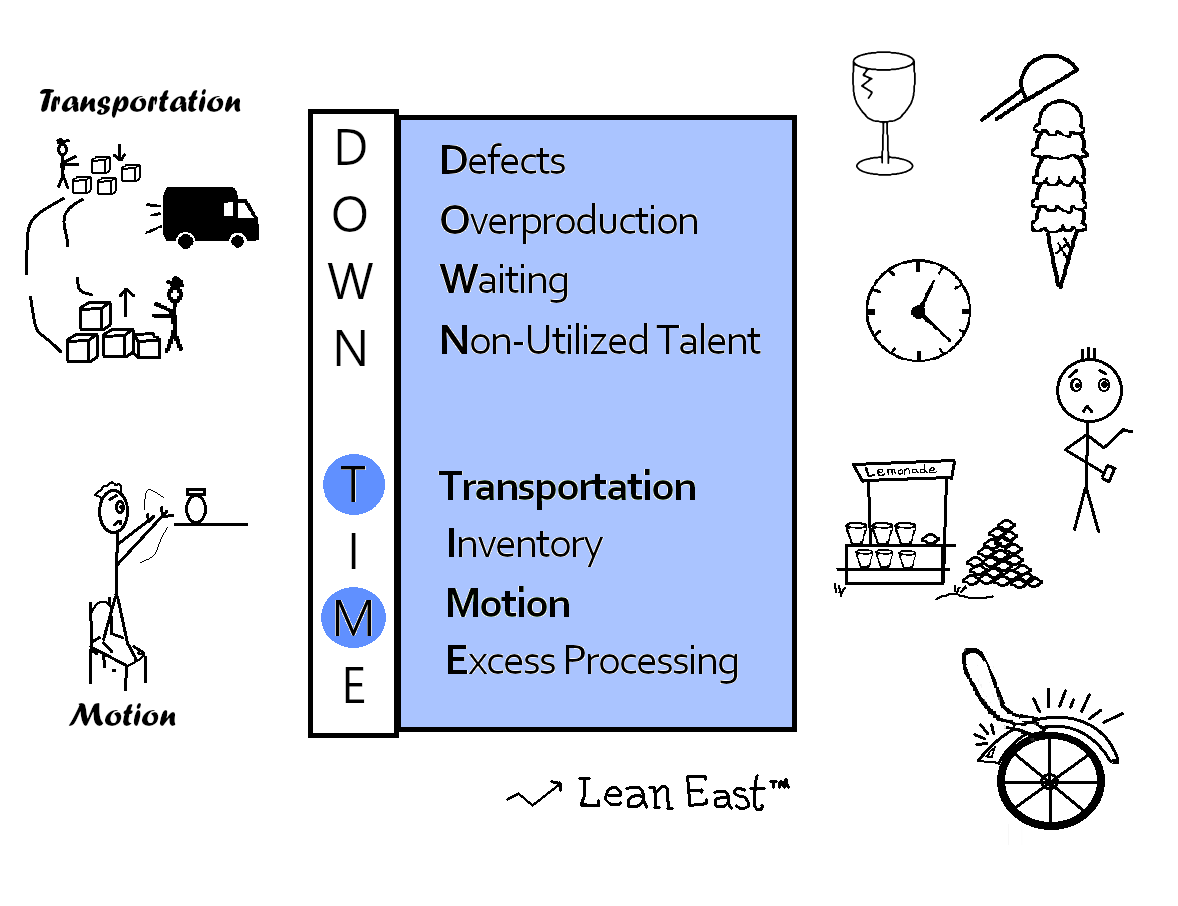

Eight Wastes Of Lean Poster Pdf The "8 wastes" in lean manufacturing are: defects, overproduction, waiting, non utilized talent, transportation, inventory excess, motion waste, and extra processing. each represents inefficiency, costing time and resources. The following blog post discusses the 8 kinds of waste in lean manufacturing, as well as providing examples used in the real world and elimination strategies to aid you in delivering continuous improvements throughout your processes. 1 transportation – unnecessary movement of materials. Do you know the 8 wastes of lean? waste in an organization is all around us. you want to be able to identify waste so that you can go about eliminating it where you can. this article will explore the most common sources of waste in any organization. In this article, we will cover each of the 8 wastes in lean manufacturing in detail, including several examples, how to spot and mitigate them, how to implement the lean manufacturing principles in a real life setting, and some lean manufacturing tools that you can use.

8 Wastes Of Lean Manufacturing Lean Vlog Do you know the 8 wastes of lean? waste in an organization is all around us. you want to be able to identify waste so that you can go about eliminating it where you can. this article will explore the most common sources of waste in any organization. In this article, we will cover each of the 8 wastes in lean manufacturing in detail, including several examples, how to spot and mitigate them, how to implement the lean manufacturing principles in a real life setting, and some lean manufacturing tools that you can use. Use the waste walk worksheet to identify wastes that you see. These seven mudas include overproduction, waiting, transportation, overprocessing, excessive inventory, unnecessary movement, and defect production. it was later that the eighth form of muda, the non use of talents, was added. The 8 wastes of lean are common inefficiencies that disrupt workflows and hinder success. they include transportation, inventory, motion, waiting, overproduction, over processing, defects, and skills. Learn how to eliminate the 8 deadly wastes that hurt your bottom line. this article delves into the 8 wastes of lean, a framework used to identify and eliminate unnecessary activities that add no value to a product or service.

The 8 Wastes Of Lean A Lifecycle Example Use the waste walk worksheet to identify wastes that you see. These seven mudas include overproduction, waiting, transportation, overprocessing, excessive inventory, unnecessary movement, and defect production. it was later that the eighth form of muda, the non use of talents, was added. The 8 wastes of lean are common inefficiencies that disrupt workflows and hinder success. they include transportation, inventory, motion, waiting, overproduction, over processing, defects, and skills. Learn how to eliminate the 8 deadly wastes that hurt your bottom line. this article delves into the 8 wastes of lean, a framework used to identify and eliminate unnecessary activities that add no value to a product or service.

8 Wastes Of Lean Examples The 8 wastes of lean are common inefficiencies that disrupt workflows and hinder success. they include transportation, inventory, motion, waiting, overproduction, over processing, defects, and skills. Learn how to eliminate the 8 deadly wastes that hurt your bottom line. this article delves into the 8 wastes of lean, a framework used to identify and eliminate unnecessary activities that add no value to a product or service.

8 Wastes Of Lean Examples

Comments are closed.