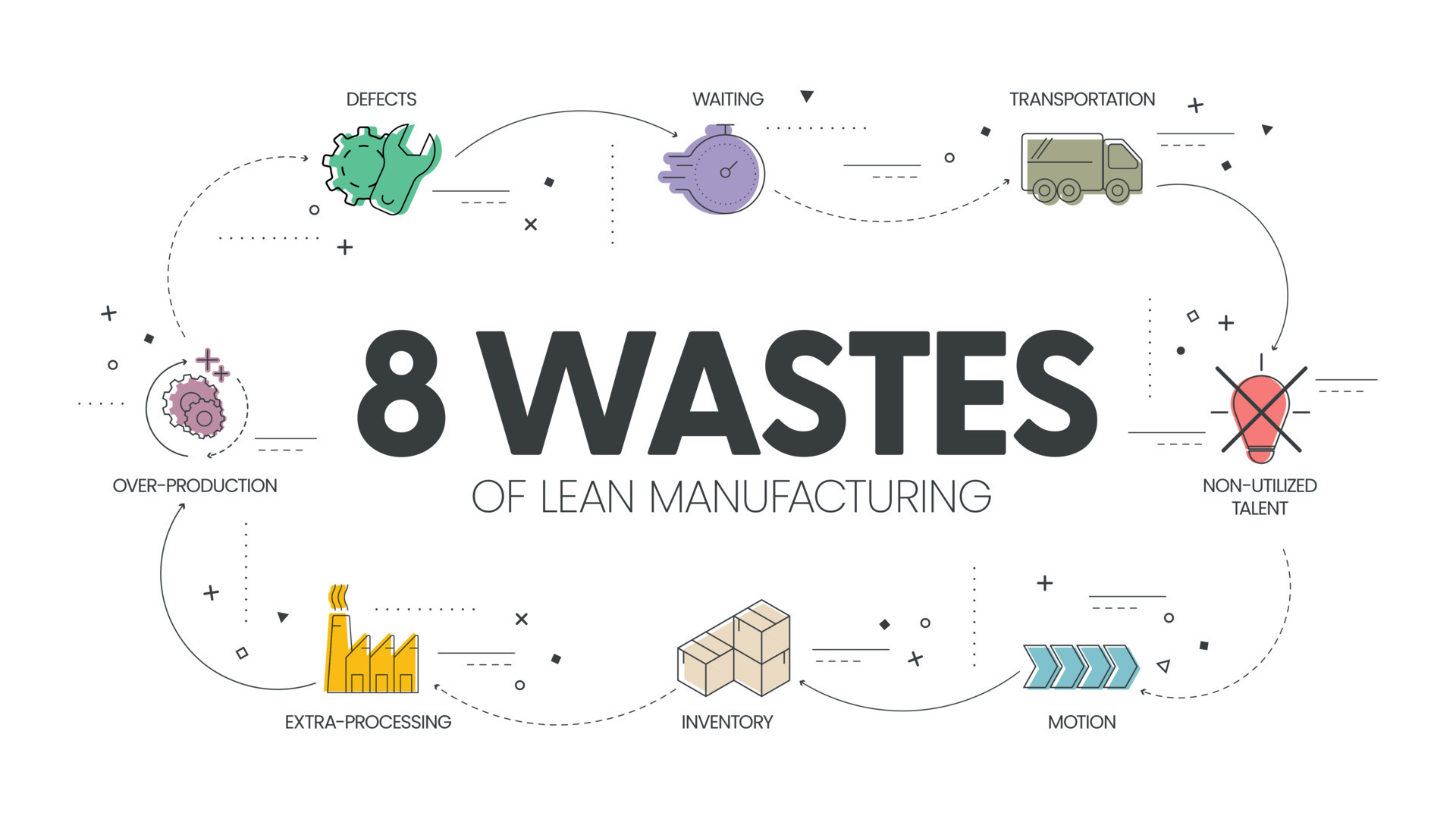

8 Wastes Of Lean Infographic

8 Wastes Of Lean Manufacturing Downtime Infographic However, wasteful activities may vary from business to business, lean theory describes these 8 wastes are common for all sort of industries. removing these wasteful steps in a process helps to improve overall efficiency in the organization. learn more about these 8 wastes of lean in this infographic by vative academy. 8 wastes infographic free download as pdf file (.pdf), text file (.txt) or read online for free. the document outlines the concept of waste in lean manufacturing, defining it as any action that does not add value to the customer.

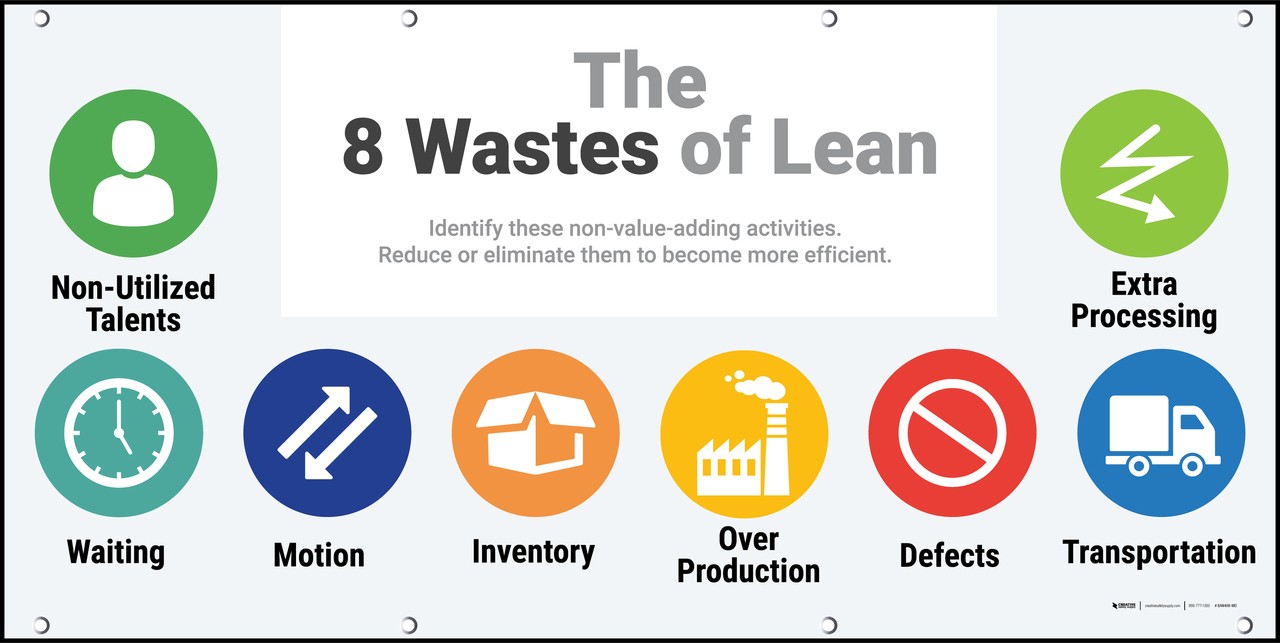

8 Wastes Of Lean Infographic We've created this "8 wastes of lean manufacturing" infographic to help you remember what waste each letter of "downtime" stands for. Download our 8 wastes of lean infographic and find out how to to identify wastes within your work processes and business systems. The eight wastes of lean refer to eight types of waste that can occur in a process, including defects, overproduction, waiting and others. Lean thinking aims to remove wastes from work processes. before diving into the 8 wastes, it is important to understand what waste is. waste is any action or step in a process that does not add value to the customer.

8 Wastes Of Lean Infographic The eight wastes of lean refer to eight types of waste that can occur in a process, including defects, overproduction, waiting and others. Lean thinking aims to remove wastes from work processes. before diving into the 8 wastes, it is important to understand what waste is. waste is any action or step in a process that does not add value to the customer. Using the acronym downtime is a great way to remember what the wastes are: identifying and addressing these wastes is fundamental to lean principles and contributes to streamlined and efficient processes. here’s a more detailed explanation of each of the 8 wastes. Download our free 8 wastes of lean manufacturing posters and use them on the factory floor noticeboards to help ensure the 8 wastes are top of mind. In the attempt to enhance the industry’s performance, researchers and professional practitioners, especially within the lean construction community listed the most important wastes which should be eliminated immediately. Overall, these 8 waste categories in lean methodology cover the vast majority of waste that you can experience either in a manufacturing environment or in daily life. as you have seen throughout this article, many of the 8 wastes are interconnected.

8 Wastes Of Lean Icons Using the acronym downtime is a great way to remember what the wastes are: identifying and addressing these wastes is fundamental to lean principles and contributes to streamlined and efficient processes. here’s a more detailed explanation of each of the 8 wastes. Download our free 8 wastes of lean manufacturing posters and use them on the factory floor noticeboards to help ensure the 8 wastes are top of mind. In the attempt to enhance the industry’s performance, researchers and professional practitioners, especially within the lean construction community listed the most important wastes which should be eliminated immediately. Overall, these 8 waste categories in lean methodology cover the vast majority of waste that you can experience either in a manufacturing environment or in daily life. as you have seen throughout this article, many of the 8 wastes are interconnected.

8 Wastes Of Lean Icons In the attempt to enhance the industry’s performance, researchers and professional practitioners, especially within the lean construction community listed the most important wastes which should be eliminated immediately. Overall, these 8 waste categories in lean methodology cover the vast majority of waste that you can experience either in a manufacturing environment or in daily life. as you have seen throughout this article, many of the 8 wastes are interconnected.

Infographic Wastes Of Lean 48 Off Brunofuga Adv Br

Comments are closed.