Applications Of Industrial Robotic Systems Industrial Robots

Top Industrial Applications In Robotic Applications Pdf Robot Robotics Industrial robots are now a common sight in numerous factories, warehouses, and sectors worldwide. discover the many ways in which they are used today. In this post, we'll cover the top 12 industrial robot applications that are shaping the present. you'll learn how these automated machines are reshaping productivity and efficiency across multiple industries.

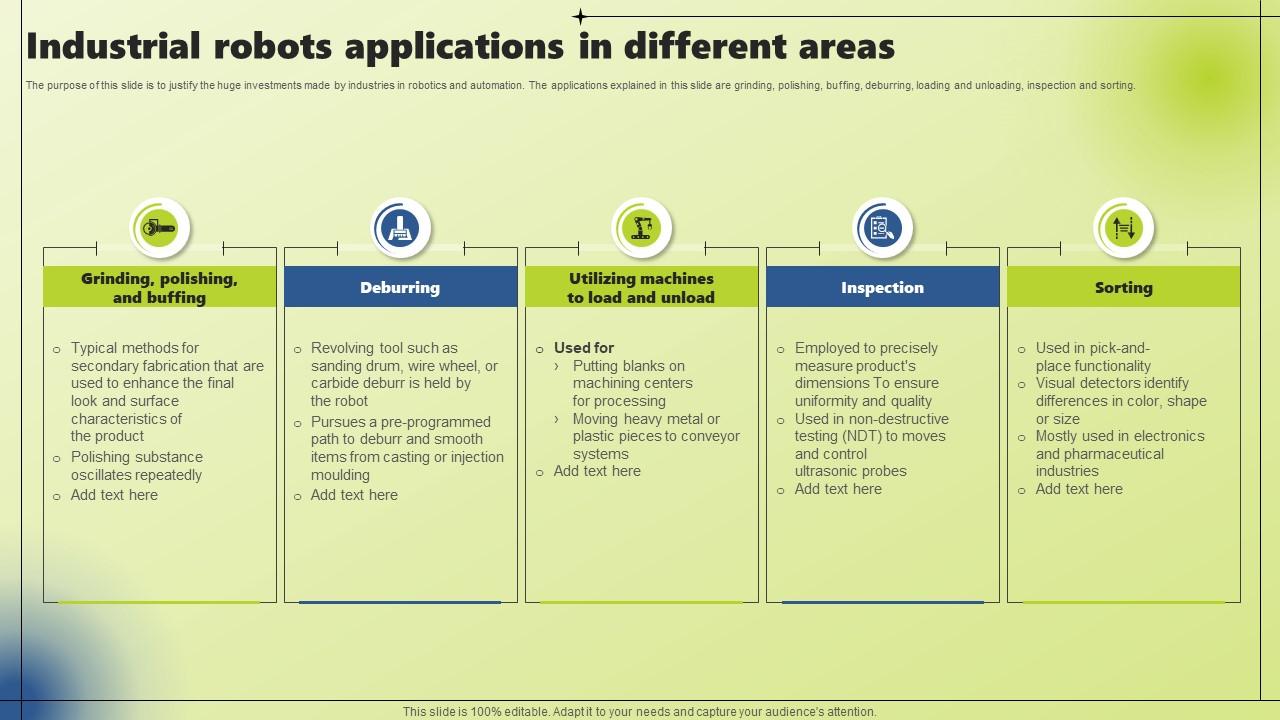

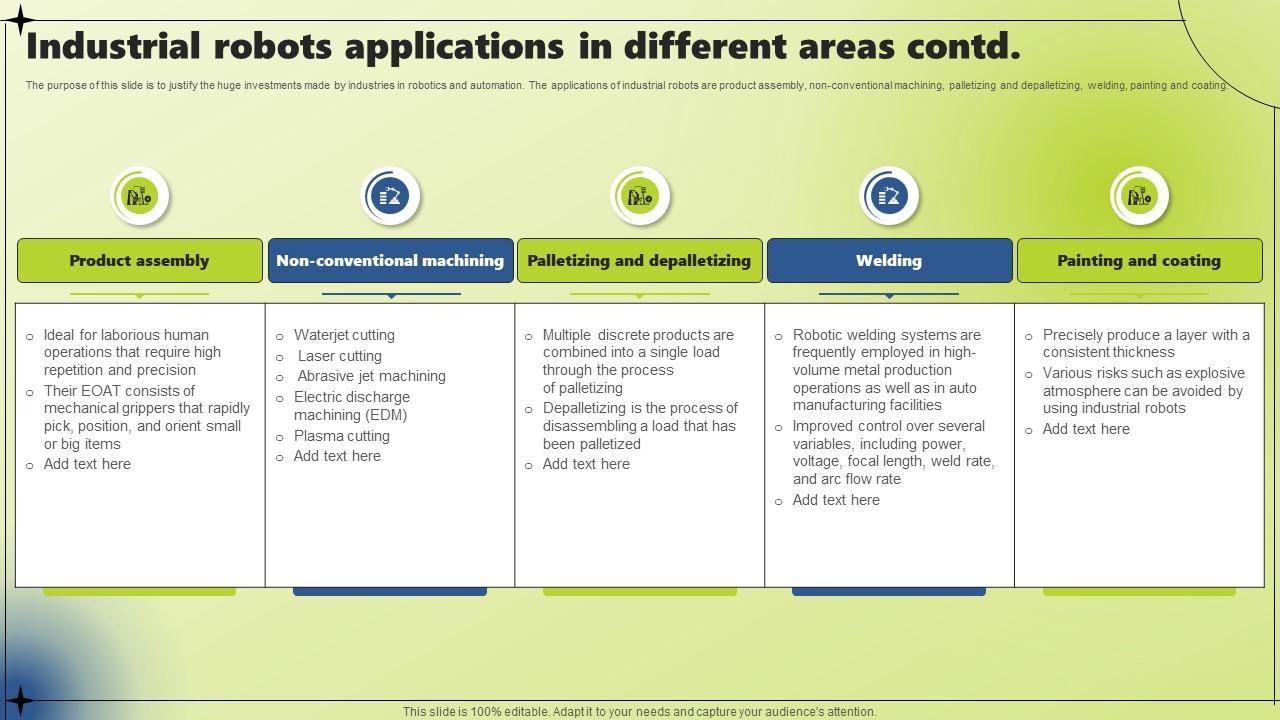

Applications Of Industrial Robotic Systems Industrial Robots Applications In Different Areas Ppt In this article, we will help you understand the most common industrial robot applications and the different types of robots used in those particular applications. so, keep reading. Robots are used for: assembly: robots perform tasks such as welding, painting, and assembling components with high precision and speed. inspection: machine vision systems enable robots to inspect parts and assemblies for defects, ensuring high quality standards. Here are the specific tasks traditional industrial robots are designed to perform: 1. arc welding. arc welding, or robot welding, became commonplace in the 1980s. one of the driving forces for switching to robot welding is improving the safety of workers from arc burn and inhaling hazardous fumes. 2. spot welding. This article explores 13 essential applications of industrial robots, showcasing their impact on productivity and safety. dive in to discover how these advancements can streamline operations and reduce labor costs in various sectors.

Applications Of Industrial Robotic Systems Industrial Robots Applications In Different Areas Ppt Here are the specific tasks traditional industrial robots are designed to perform: 1. arc welding. arc welding, or robot welding, became commonplace in the 1980s. one of the driving forces for switching to robot welding is improving the safety of workers from arc burn and inhaling hazardous fumes. 2. spot welding. This article explores 13 essential applications of industrial robots, showcasing their impact on productivity and safety. dive in to discover how these advancements can streamline operations and reduce labor costs in various sectors. These robotic systems are integral to modern industrial practices, enabling more efficient operations and reducing human error. here, we explore the top 10 applications of industrial robots, showcasing their versatility and vital roles in diverse sectors. We’ll walk you through common robot types, from traditional industrial robots to cutting edge collaborative and mobile robots. by the end, you’ll better understand the applications of these robots and how they can help boost productivity, streamline workflows, and enhance safety in your industry. what we’ll cover:. At its core, an industrial robot is an automatically controlled, reprogrammable, multi purpose manipulator, programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications. Industrial robots have evolved from simple programmable machines to sophisticated ai powered systems that can work alongside humans, learn from their environments, and perform increasingly complex tasks.

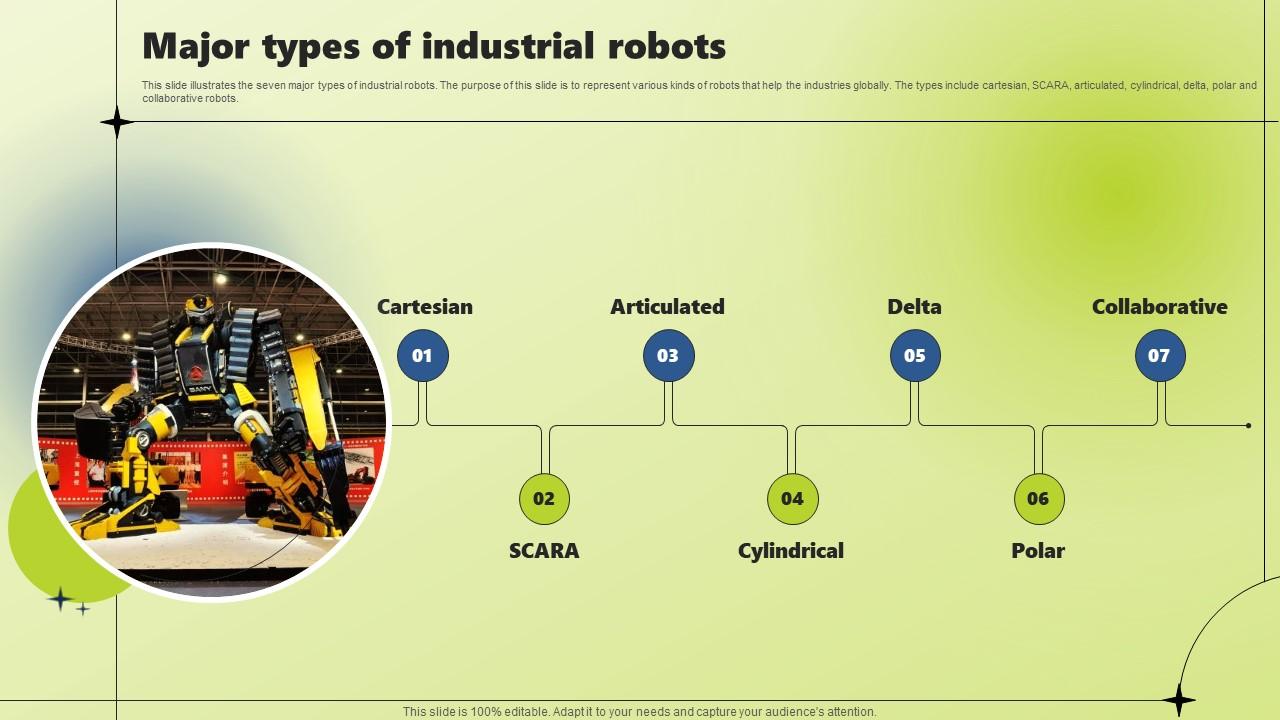

Applications Of Industrial Robotic Systems Major Types Of Industrial Robots Ppt Example These robotic systems are integral to modern industrial practices, enabling more efficient operations and reducing human error. here, we explore the top 10 applications of industrial robots, showcasing their versatility and vital roles in diverse sectors. We’ll walk you through common robot types, from traditional industrial robots to cutting edge collaborative and mobile robots. by the end, you’ll better understand the applications of these robots and how they can help boost productivity, streamline workflows, and enhance safety in your industry. what we’ll cover:. At its core, an industrial robot is an automatically controlled, reprogrammable, multi purpose manipulator, programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications. Industrial robots have evolved from simple programmable machines to sophisticated ai powered systems that can work alongside humans, learn from their environments, and perform increasingly complex tasks.

Industrial Robots Challenges And Possible Solutions Applications Of Industrial Robotic Systems At its core, an industrial robot is an automatically controlled, reprogrammable, multi purpose manipulator, programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications. Industrial robots have evolved from simple programmable machines to sophisticated ai powered systems that can work alongside humans, learn from their environments, and perform increasingly complex tasks.

Industrial Robots For Various Applications Universal Robotic Inc

Comments are closed.