Bill Of Materials Bom How To Make Bom Types Of Bom

Bill Of Materials Bom Meaning Purpose And Types 54 Off Whether you’re assembling a piece of furniture, crafting a pizza, or building complex machinery, a bom keeps everything organized: the parts, the quantities, and the steps. in this guide, we’ll explain what a bom is, who needs it, how to create one, and why excel may not be your best option anymore. Creating a bill of materials (bom) is a crucial step in the manufacturing and production process. whether you are building simple or complex products, following these 10 steps ensures you capture all necessary components, quantities, and processes required to produce a product effectively.

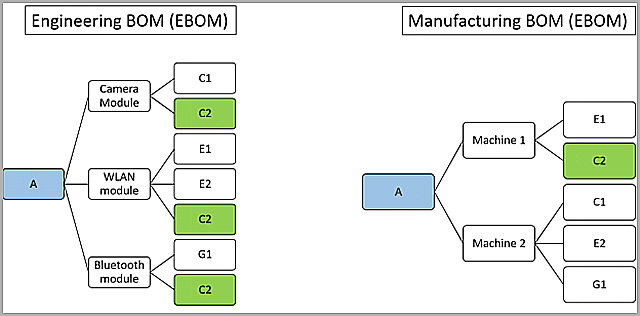

Bill Of Materials Bom Definition Types Examples Video Hot Sex Picture In this guide, we’ll explore what makes up a bom, its different types, and best practices for creating and managing one. a bill of materials (bom) is more than just a list; it’s a detailed document that enumerates all the materials and components needed to create a product. Bill of materials contains specifications of every item required to manufacture the products. learn what is bill of materials and the top 10 types of bom. A bill of materials (bom) is a comprehensive list of all the components, parts, raw materials, subassemblies, and associated quantities needed to manufacture a product. There are several types of boms used in manufacturing. bills of materials can be divided into types by their function or their current product lifecycle stage, by their configurability, or by their structure. let’s take a look at three different ways to categorize them: 1. engineering bill of materials.

Bill Of Materials Bom Definition Examples Types Vrogue Co A bill of materials (bom) is a comprehensive list of all the components, parts, raw materials, subassemblies, and associated quantities needed to manufacture a product. There are several types of boms used in manufacturing. bills of materials can be divided into types by their function or their current product lifecycle stage, by their configurability, or by their structure. let’s take a look at three different ways to categorize them: 1. engineering bill of materials. We’ll cover the basics of a bill of materials, explore different types of boms, and show you how to create a bill of materials with the help of ags devices. streamline your procurement process. what is a bill of materials (bom)? 1. engineering bom (ebom) 2. manufacturing bom (mbom) 3. sales and service boms. 4. single vs. multi level boms. 1. Bill of material more popularly known as ‘bom’ is a key function of businesses who are engaged in manufacturing inventories. bill of material (bom) helps the manufacturing unit to design, plan inventories, determine cots estimation etc. Accurate boms should ensure all resources are available and efficiently deployed to support the production schedule. integrated demand and supply planning solutions like netstock use the boms to automate inventory replenishment and improve production planning. Bills of materials a bill of materials (bom) defines the components that are required in order to produce a product. the components can be raw materials, semi finished products, or ingredients. in some cases, services can be referenced in a bom. however, boms typically describe the material resources that are required.

Bill Of Materials Bom Definition Examples Types Vrogue Co We’ll cover the basics of a bill of materials, explore different types of boms, and show you how to create a bill of materials with the help of ags devices. streamline your procurement process. what is a bill of materials (bom)? 1. engineering bom (ebom) 2. manufacturing bom (mbom) 3. sales and service boms. 4. single vs. multi level boms. 1. Bill of material more popularly known as ‘bom’ is a key function of businesses who are engaged in manufacturing inventories. bill of material (bom) helps the manufacturing unit to design, plan inventories, determine cots estimation etc. Accurate boms should ensure all resources are available and efficiently deployed to support the production schedule. integrated demand and supply planning solutions like netstock use the boms to automate inventory replenishment and improve production planning. Bills of materials a bill of materials (bom) defines the components that are required in order to produce a product. the components can be raw materials, semi finished products, or ingredients. in some cases, services can be referenced in a bom. however, boms typically describe the material resources that are required.

Bill Of Materials Bom What Is Bom And How To Make A Bom 2023 Accurate boms should ensure all resources are available and efficiently deployed to support the production schedule. integrated demand and supply planning solutions like netstock use the boms to automate inventory replenishment and improve production planning. Bills of materials a bill of materials (bom) defines the components that are required in order to produce a product. the components can be raw materials, semi finished products, or ingredients. in some cases, services can be referenced in a bom. however, boms typically describe the material resources that are required.

Bill Of Materials Bom What S The Purpose Of It Engisoft Engineering

Comments are closed.