Creo Ansys Simulation How To Create Shell Idealizations

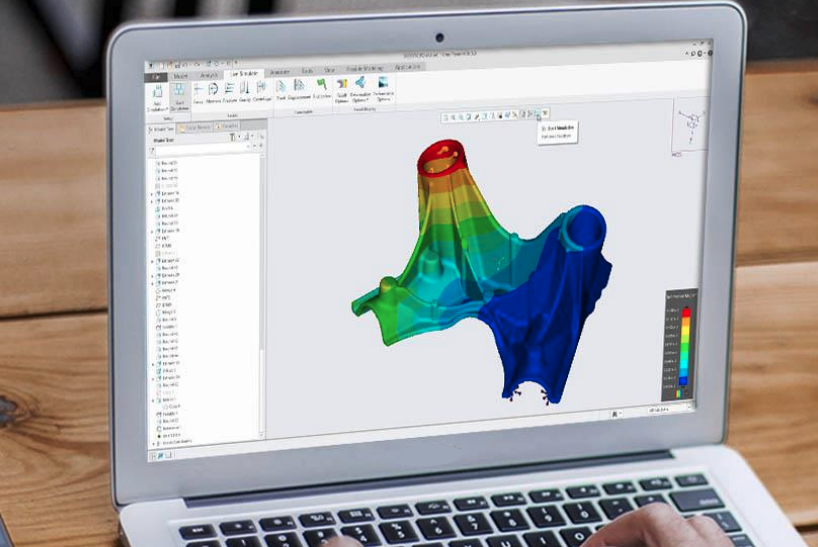

Webinar Accelerate Product Innovation With Creo Simulation Live Powered By Ansys Engineering This creo parametric tutorial shows how to create shell elements in both solid and surface geometry in creo ansys simulation for finite element analysis (fea. You can use shell idealizations to model a thin region of a constant defined thickness for a part. if the part, or region is relatively thin compared to its length and width, use a shell to simplify the model and reduce computation time.

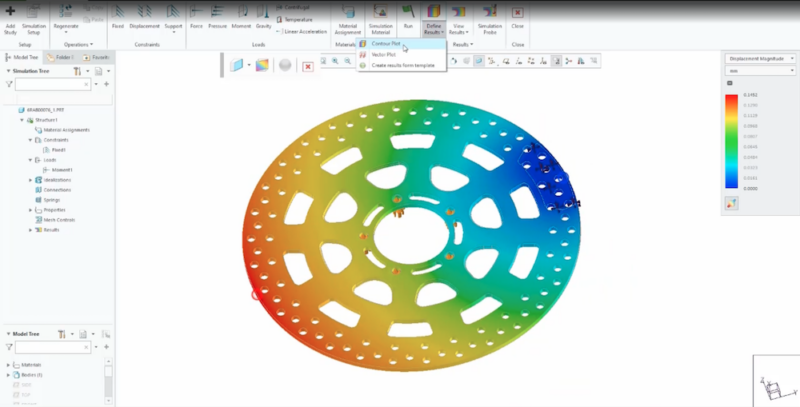

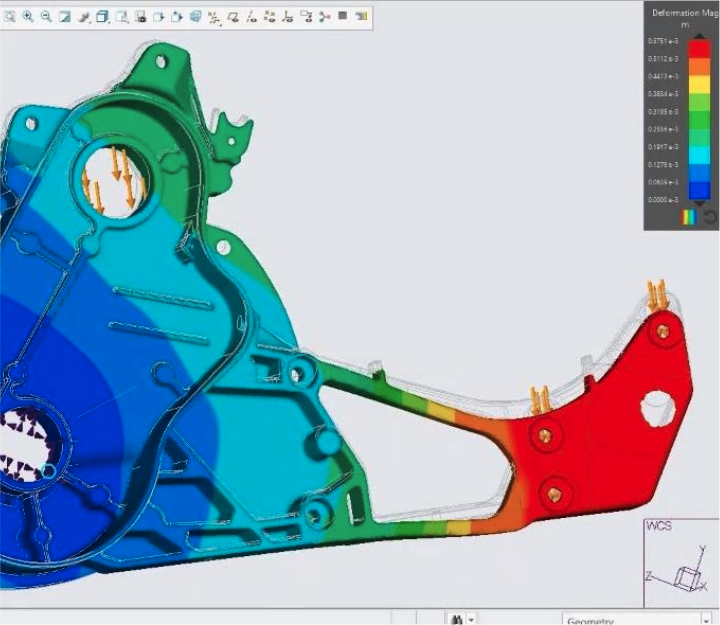

Creo Ansys Simulation Everything You Need To Know About Creo Ansys Creo Windchill And Ptc Creo simulates (pro mechanica) provides the powerful option shell pair for extracting mid plane from the solid model. analysis with the mid plane efficiently savings the time taken and the disk space for an analysis. Shell elements are used to create a mathematical 2d idealization of a 3d structure. they offer computationally efficient solutions for modelling shell structures when compared to solid elements. the discussion in this chapter applies to 3d finite strain shell elements such as shell181 and shell281. compared to other shells, these shell elements. This creo parametric tutorial shows how to create simple shell idealizations on surface geometry in creo simulate.for more information, visit cre. Shell pairs are used to model thin walled areas of a model as shells rather than solids for simulation. the defined shell pairs are compressed to a shell surface (sometimes also called a “mid surface” because it is usually placed mid distance between the shell pair surfaces.).

Creo Ansys Simulation Everything You Need To Know About Creo Ansys Creo Windchill And Ptc This creo parametric tutorial shows how to create simple shell idealizations on surface geometry in creo simulate.for more information, visit cre. Shell pairs are used to model thin walled areas of a model as shells rather than solids for simulation. the defined shell pairs are compressed to a shell surface (sometimes also called a “mid surface” because it is usually placed mid distance between the shell pair surfaces.). With creo ansys simulation, you can perform structural, thermal, and modal simulations by applying materials, loads, and constraints to your creo parametric models. you can further refine the auto generated mesh as necessary and create mass, spring, shell, and beam idealizations. Click the shell tool in the create ribbon group on the design tab. mouse over the solids in your design to highlight the faces that could be removed. (optional) enter a value into the dimension field to change the thickness of the shell. Use the line sketching tool to create a vertical line starting from the x axis . hover the cursor around the axis until you see a symbol c to begin your sketch. the symbol c means the line is coincident with the x axis. next, use the arc by center to create the dome of the shell. Is there a way in creo simulate to use a surface to create shell elements? this is not a midsurface shell compression. i created a simple "l" solid part with a surface extrusion.

Creo Ansys Simulation Everything You Need To Know About Creo Ansys Creo Windchill And Ptc With creo ansys simulation, you can perform structural, thermal, and modal simulations by applying materials, loads, and constraints to your creo parametric models. you can further refine the auto generated mesh as necessary and create mass, spring, shell, and beam idealizations. Click the shell tool in the create ribbon group on the design tab. mouse over the solids in your design to highlight the faces that could be removed. (optional) enter a value into the dimension field to change the thickness of the shell. Use the line sketching tool to create a vertical line starting from the x axis . hover the cursor around the axis until you see a symbol c to begin your sketch. the symbol c means the line is coincident with the x axis. next, use the arc by center to create the dome of the shell. Is there a way in creo simulate to use a surface to create shell elements? this is not a midsurface shell compression. i created a simple "l" solid part with a surface extrusion.

Creo Ansys Simulation Engineering Simulation Software Ptc Use the line sketching tool to create a vertical line starting from the x axis . hover the cursor around the axis until you see a symbol c to begin your sketch. the symbol c means the line is coincident with the x axis. next, use the arc by center to create the dome of the shell. Is there a way in creo simulate to use a surface to create shell elements? this is not a midsurface shell compression. i created a simple "l" solid part with a surface extrusion.

Comments are closed.