Creo Simulate 1p0 Thermal Analysis Command Line Interface

Creo Simulate 1p0 Pdf Click simulate to start the transient thermal simulation. a changing fringe plot displays as the simulation runs. click pause simulation if you want to pause the simulation. Thermal expansion is relative; there will always be a point that has zero expansion. are you trying to get your cube to expand relative to the center? if so, then the easiest solution is to use symmetry.

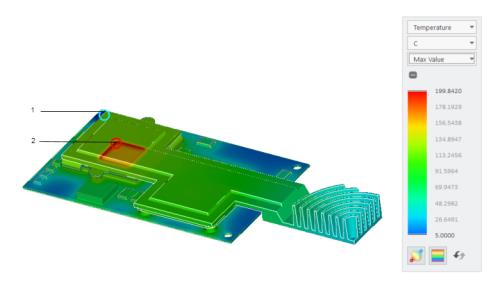

Example Thermal Simulation This creo parametric tutorial video shows how to perform a thermal analysis using creo simulation live, including defining prescribed temperatures, heat load. –more accurate modeling of the interface between bolted components –modeling of bending and torsion effects of bolts –new measure calculations for forces and moments in the bolt and at the interface preload on bolts modeled as solids –automates complex modeling technique (workaround) for preloads. Define a contact interface to indicate the curves or surfaces on which creo simulate considers the effect of load during a static analysis with contacts. you can define contact interfaces for the following reference types:. You can set up a thermal simulation on your model using creo simulate live. you can apply boundary conditions and heat loads to simulate the thermal effects on your model.

Creo Simulate With Preload Ptc Community Define a contact interface to indicate the curves or surfaces on which creo simulate considers the effect of load during a static analysis with contacts. you can define contact interfaces for the following reference types:. You can set up a thermal simulation on your model using creo simulate live. you can apply boundary conditions and heat loads to simulate the thermal effects on your model. Creo ansys simulation allows you to simulate thermal conditions. a steady state thermal analysis calculates effects of constant thermal loads on a model and is used to determine temperatures, heat flow rates, and the heat fluxes in a part. In addition to its native solver, thermal's integrated mode offers specialized analyses that automatically create fully associative fea meshes for third party finite element solvers. Run a thermal simulation to calculate the thermal response to heat loads, depending on the prescribed temperatures, applied convection conditions or both. you can run the following types of thermal analyses:. The product line features two modules —structure and thermal—each of which solves for a different family of mechanical behaviors. structure focuses on the structural integrity of your model, while thermal evaluates heat transfer characteristics.

Creo Simulate Contact Analysis Issue Ptc Community Creo ansys simulation allows you to simulate thermal conditions. a steady state thermal analysis calculates effects of constant thermal loads on a model and is used to determine temperatures, heat flow rates, and the heat fluxes in a part. In addition to its native solver, thermal's integrated mode offers specialized analyses that automatically create fully associative fea meshes for third party finite element solvers. Run a thermal simulation to calculate the thermal response to heat loads, depending on the prescribed temperatures, applied convection conditions or both. you can run the following types of thermal analyses:. The product line features two modules —structure and thermal—each of which solves for a different family of mechanical behaviors. structure focuses on the structural integrity of your model, while thermal evaluates heat transfer characteristics.

Comments are closed.