How Is The Lifter Comes Out From Sliders Plastic Injection Mould Design

Injection Mold Slide And Lifter Design Guideline Injection Mold Design Lifters enable the creation of undercuts, moving vertically across the mould, while sliders provide slides or grooves onto surfaces – they move horizontally through injection molds. Heya mould is a professional plastic mold factory of molds and injections. it has a professional product design team, a mold flow analysis team, a mold design team and a precision.

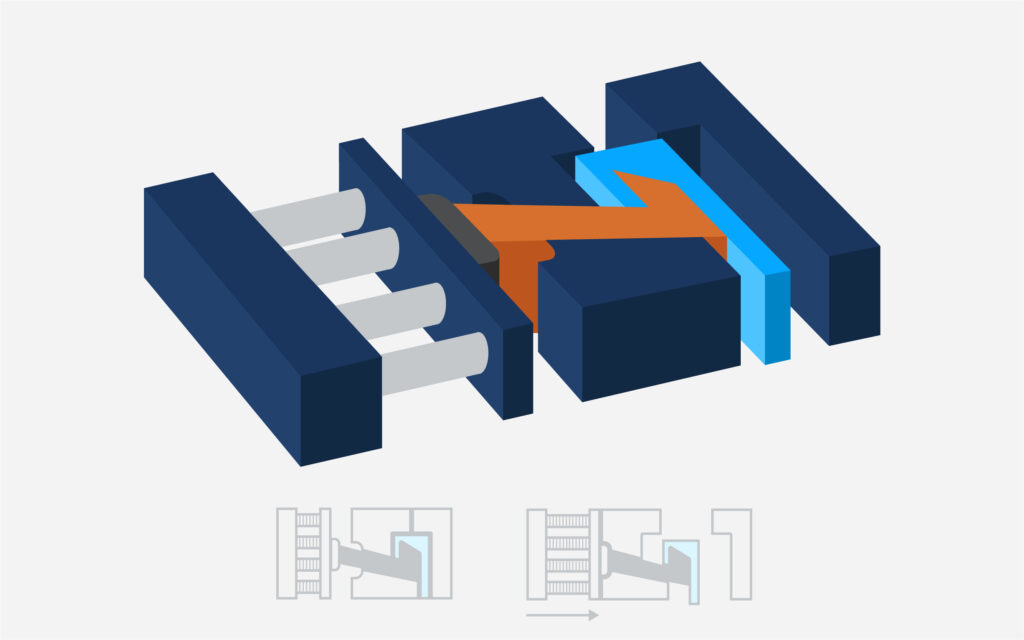

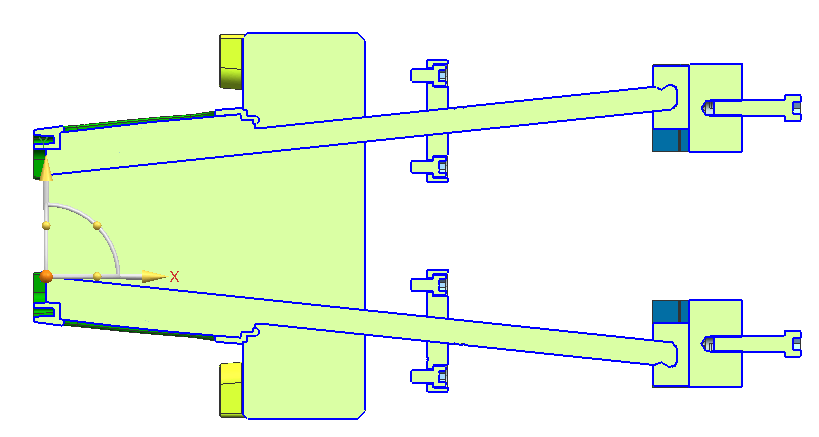

How Is The Lifter Comes Out From Sliders Plastic Injection Mould Design Plastic Injection During mold opening, ejector plates push upward, moving ejector pins—and simultaneously pushing the lifters outward due to their inclined orientation. this combined vertical and horizontal motion lifts the part clear of the undercut. In this article, we will introduce the differences between slider and tilt top of injection mold in detail to help readers better understand and apply these two mechanisms. Learn about the mold lifter in injection mold, from design principles to key components, enhancing part ejection and manufacturing efficiency. Injection molding lifters consist of a blade like or pin like lifting mechanism, an ejector plate, and a retainer plate. there’s also a block like locking mechanism. unlike a slider, which pushes the injection molded part to one side, a lifter pushes the part upward and at an angle.

Injection Molding Lifter Design A Full Guide Fow Mould Learn about the mold lifter in injection mold, from design principles to key components, enhancing part ejection and manufacturing efficiency. Injection molding lifters consist of a blade like or pin like lifting mechanism, an ejector plate, and a retainer plate. there’s also a block like locking mechanism. unlike a slider, which pushes the injection molded part to one side, a lifter pushes the part upward and at an angle. Lifters are typically driven by the ejector plate and require careful design to ensure smooth operation and prevent part damage. they are essential for producing parts with complex internal geometries while maintaining high precision and efficiency during molding. Lifters facilitate manufacture of multiple parts in a single mold improving production efficiency. they provide versatility in production through molding of various parts with varying geometries. this is the initial step in designing an injection mold lifter. Sliders and lifters are key components in injection molding tools used to form complex plastic parts. while both are used to release undercuts and complex geometries, they differ in function, design, and application. Choosing between an injection molding lifter and slider depends on several factors, including the part design, complexity, production requirements, and cost considerations.

Injection Molding Lifter Design A Full Guide Fow Mould Lifters are typically driven by the ejector plate and require careful design to ensure smooth operation and prevent part damage. they are essential for producing parts with complex internal geometries while maintaining high precision and efficiency during molding. Lifters facilitate manufacture of multiple parts in a single mold improving production efficiency. they provide versatility in production through molding of various parts with varying geometries. this is the initial step in designing an injection mold lifter. Sliders and lifters are key components in injection molding tools used to form complex plastic parts. while both are used to release undercuts and complex geometries, they differ in function, design, and application. Choosing between an injection molding lifter and slider depends on several factors, including the part design, complexity, production requirements, and cost considerations.

Injection Molding Lifter Design A Full Guide Fow Mould Sliders and lifters are key components in injection molding tools used to form complex plastic parts. while both are used to release undercuts and complex geometries, they differ in function, design, and application. Choosing between an injection molding lifter and slider depends on several factors, including the part design, complexity, production requirements, and cost considerations.

Lifter Design For Plastic Injection Mold Plastic Injection Molding And Mold Maker Manufacturing

Comments are closed.