How To Design Compression Spring

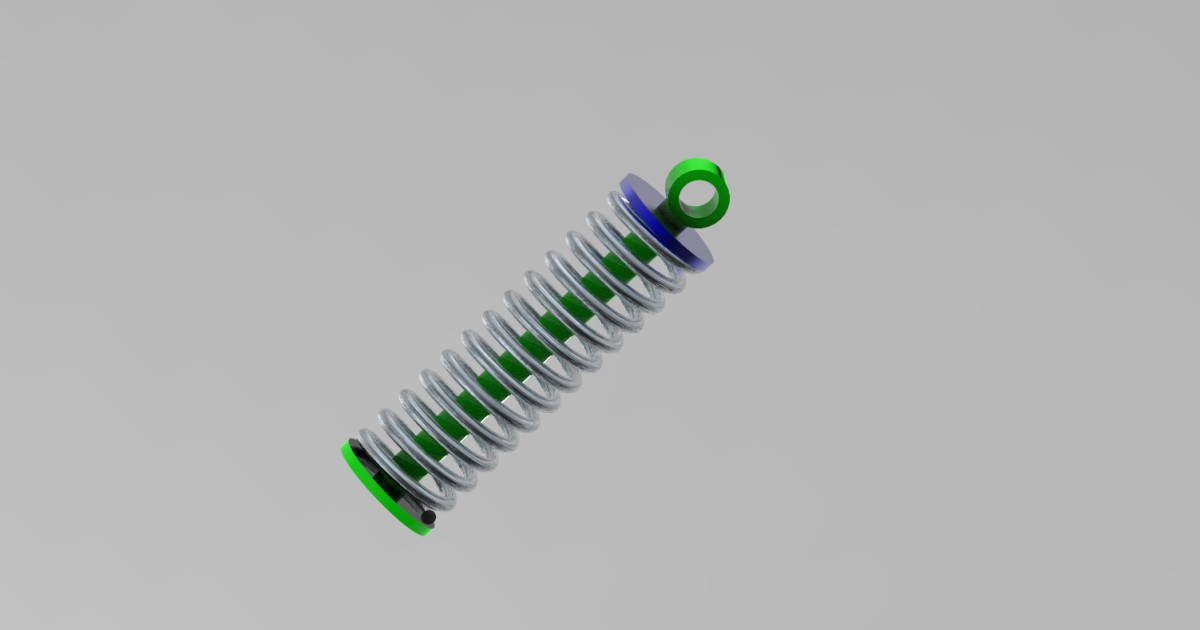

Compression Spring Autodesk Community Gallery A guide to designing compression springs providing the user with several compression spring formulas and compression spring calculations which are required to achieve a functional compression spring design. When designing or selecting a compression spring the following items need to be considered: one crucial thing to understand when designing compression springs is to be sure to operate them in their intended range.

Design Of Compression Spring Spring And Wire Forming China This article tackles the different compression spring formulas in order to guide designers in the design of systems that use this component. compression spring rate formula. inherently, the behavior of a compression spring is governed by its spring rate or spring constant. There are a number of design considerations to consider when working with compression springs. let us first consider stress, set and weight as important considerations in establishing a custom spring design which need to be understood at the outset. Explore our range of high grade compression springs and get tips on choosing the right one for your needs with our compression spring selection guide. First, measure your compression spring ’s surroundings to ensure that the dimensions you decide upon will not affect the spring when installed. if it is going over a shaft or hole, you must be vigilant about the inner and outer diameters.

Guide To Compression Spring Design Explore our range of high grade compression springs and get tips on choosing the right one for your needs with our compression spring selection guide. First, measure your compression spring ’s surroundings to ensure that the dimensions you decide upon will not affect the spring when installed. if it is going over a shaft or hole, you must be vigilant about the inner and outer diameters. Stress considerations: design the spring to stay within the allowable stress limit when the spring is fully compressed or “bottomed.” this can be done when there is sufficient space available in the mechanism, and economy is not a consideration. The design and selection of these springs, albeit based on simple mechanics, are crucial to the functionality and efficiency of the systems they are part of. this article will guide you through the process of designing and selecting a compression spring. Compression springs are designed to operate with a compressive load. as the name suggests, compression springs are compressed under a load or force thus storing elastic energy and then releasing it to return to their original uncompressed length. This calculator computes all parameters (spring rate, maximum load, maximum stress, solid height, coil pitch, coil angle, wire length, resonant frequency, shear modulus, and spring mass) related to a compression spring from basic geometry and material data input.

Compression Spring Design What You Really Need To Know Mentored Engineer Stress considerations: design the spring to stay within the allowable stress limit when the spring is fully compressed or “bottomed.” this can be done when there is sufficient space available in the mechanism, and economy is not a consideration. The design and selection of these springs, albeit based on simple mechanics, are crucial to the functionality and efficiency of the systems they are part of. this article will guide you through the process of designing and selecting a compression spring. Compression springs are designed to operate with a compressive load. as the name suggests, compression springs are compressed under a load or force thus storing elastic energy and then releasing it to return to their original uncompressed length. This calculator computes all parameters (spring rate, maximum load, maximum stress, solid height, coil pitch, coil angle, wire length, resonant frequency, shear modulus, and spring mass) related to a compression spring from basic geometry and material data input.

How To Design Compression Spring Compression springs are designed to operate with a compressive load. as the name suggests, compression springs are compressed under a load or force thus storing elastic energy and then releasing it to return to their original uncompressed length. This calculator computes all parameters (spring rate, maximum load, maximum stress, solid height, coil pitch, coil angle, wire length, resonant frequency, shear modulus, and spring mass) related to a compression spring from basic geometry and material data input.

Understanding Compression Springs A Guide For Innovators And Manufacturers

Comments are closed.