Implementing The 5 Core Lean Principles Riset

Implementing The 5 Core Lean Principles Riset Lean management is a systematic approach to improving efficiency by eliminating waste, optimizing processes, and increasing value for customers. originating from the toyota production system, lean management focuses on delivering more value with fewer resources. Return to the first step and begin the next lean transformation, offering a product which is ever more nearly what the customer wants.

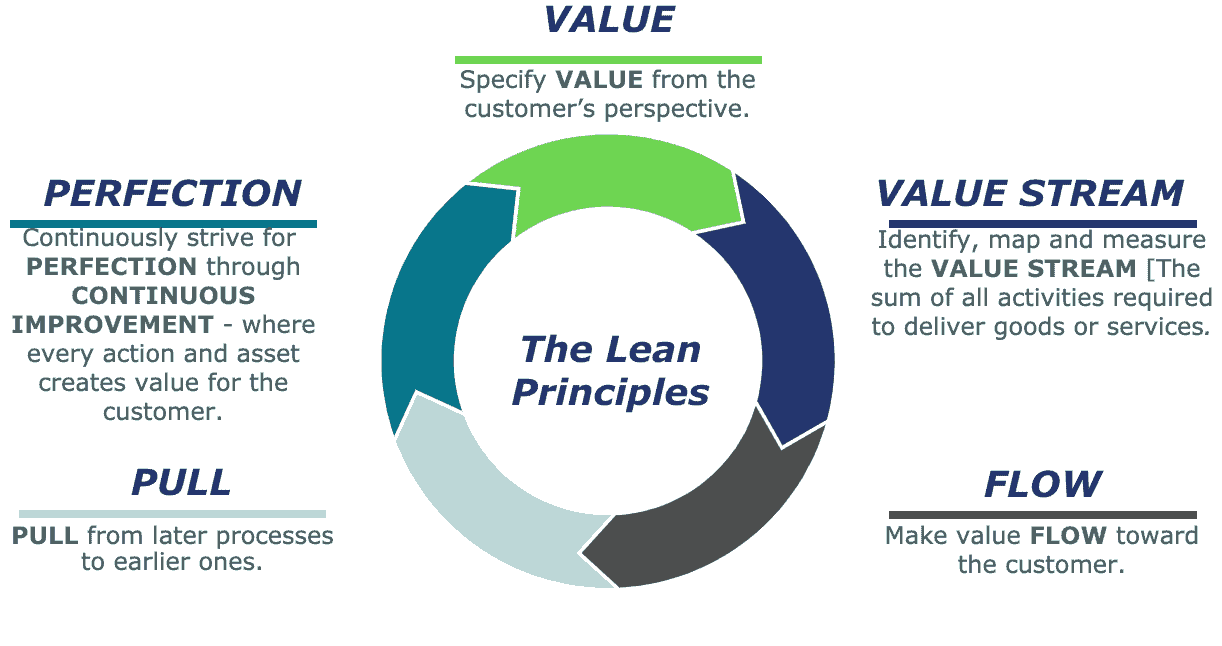

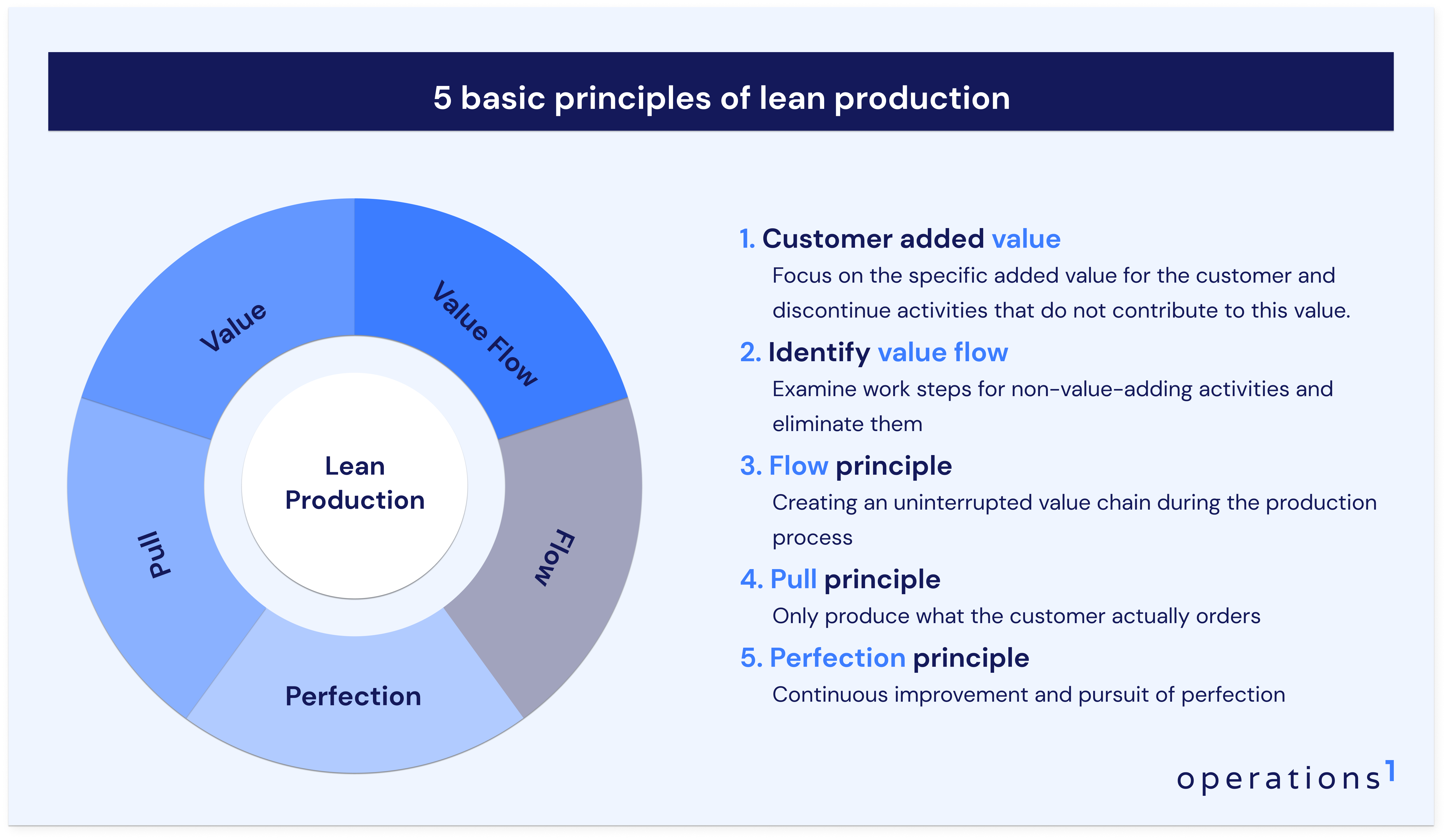

The Five Principles Of Lean Pdf Lean Manufacturing Production And Manufacturing Throughout this article, i will explain the five principles of lean manufacturing, highlight key lean tools that you can use to apply these principles, and provide examples of each principle in both the manufacturing environment and daily life. Discover the 5 lean principles: identify value, map the value stream, create flow, establish a pull system, and drive continuous improvement. learn how to apply lean management to reduce waste and boost efficiency in your organization. We’ll examine each principle in detail, looking at key concepts, implementation strategies, challenges, and real world examples. understanding and applying these principles is essential for any organization looking to adopt lean practices and create a culture of continuous improvement. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection.

5 Lean Principles For Maximizing Value And Minimizing Waste Pdf We’ll examine each principle in detail, looking at key concepts, implementation strategies, challenges, and real world examples. understanding and applying these principles is essential for any organization looking to adopt lean practices and create a culture of continuous improvement. The five principles are considered a recipe for improving workplace efficiency and include: 1) defining value, 2) mapping the value stream, 3) creating flow, 4) using a pull system, and 5) pursuing perfection. Mastering these five lean principles isn’t just about cutting costs—it’s about creating a culture of efficiency, innovation, and customer centric thinking. whether you’re new to lean or looking to level up, these principles are the foundation of a truly optimized process. This article will teach you the five lean principles and implementation strategies for significant product efficiency and quality improvements. what is lean? lean involves making deliberate and stringent efforts to eliminate waste. Implementing the 5 principles of lean while understanding the 5 principles of lean is important, putting them into practice is key to unlocking the full benefits. implementing lean principles requires a systematic approach and commitment across the entire organization. Lean principles are fundamental guidelines that help businesses achieve this by streamlining processes and eliminating inefficiencies. this article delves deeply into the five lean principles, providing detailed explanations and examples of their application in a manufacturing company.

5 Lean Manufacturing Principles In Times Of Digitalization Riset Mastering these five lean principles isn’t just about cutting costs—it’s about creating a culture of efficiency, innovation, and customer centric thinking. whether you’re new to lean or looking to level up, these principles are the foundation of a truly optimized process. This article will teach you the five lean principles and implementation strategies for significant product efficiency and quality improvements. what is lean? lean involves making deliberate and stringent efforts to eliminate waste. Implementing the 5 principles of lean while understanding the 5 principles of lean is important, putting them into practice is key to unlocking the full benefits. implementing lean principles requires a systematic approach and commitment across the entire organization. Lean principles are fundamental guidelines that help businesses achieve this by streamlining processes and eliminating inefficiencies. this article delves deeply into the five lean principles, providing detailed explanations and examples of their application in a manufacturing company.

The 5 Lean Principles Explained Implementing the 5 principles of lean while understanding the 5 principles of lean is important, putting them into practice is key to unlocking the full benefits. implementing lean principles requires a systematic approach and commitment across the entire organization. Lean principles are fundamental guidelines that help businesses achieve this by streamlining processes and eliminating inefficiencies. this article delves deeply into the five lean principles, providing detailed explanations and examples of their application in a manufacturing company.

Comments are closed.