Lean Principle Value Add Vs Non Value Add

Lean Principle Value Add Vs Non Value Add For something to be add value, three things must happen: anything that doesn’t accomplish this is a waste – or a non value added. it should be reduced or eliminated. the japanese word for this is “muda,” which can mean be translated into “uselessness.” that gives you some idea of the view on waste. Value added vs. non value added are key concepts in process improvement methodologies, particularly in lean manufacturing and six sigma. value added (va) activities are those that, in the eyes of the customer, enhance the product or service, making it worth more or more desirable.

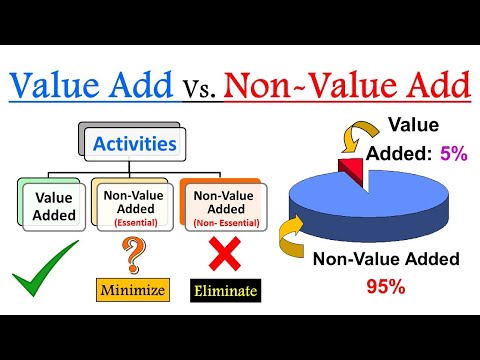

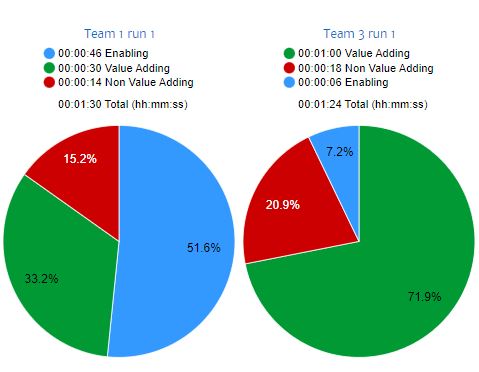

Value Add Vs Non Value Added Lean Value Added Vs Non Value Added Examples Value Added Analysis Value added processes make meaningful and worthwhile contributions to the quality of the deliverable, while nvas do not. it’s important to note that many value adding processes do have nva components within them. these differences are revealed as businesses analyze and map their processes to a finer degree. “only an activity that physically changes the shape or character of a product or assembly can add value.” “any activity that does not change the product or assembly is waste.” however even this can fall short in some areas, consider the case of conducting a roughing cut, or in over polishing a surface that will never been seen. Lean waste refers to all activities that do not add any value to the product or service and respectfully to your customers. simply put, non value added activities are everything a customer would not be willing to pay for; hence, they bring waste (inefficiencies) to your process. however, does this mean all waste is redundant?. Understanding value added vs non value added supports organizations in their pursuit of lean operations and continuous improvement. properly differentiating between these categories through detailed process mapping and analysis allows for data driven waste reduction, lead time declines, and quality enhancement.

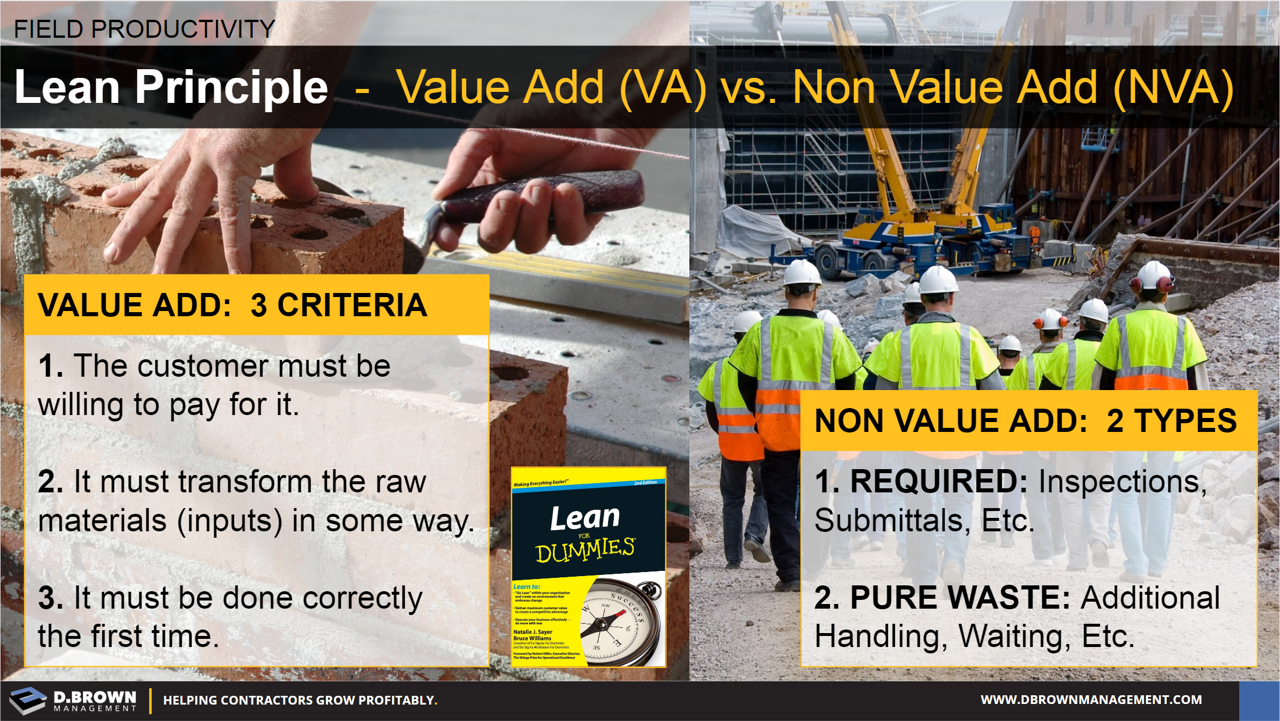

Value Add Vs Non Value Adding Processes Lean waste refers to all activities that do not add any value to the product or service and respectfully to your customers. simply put, non value added activities are everything a customer would not be willing to pay for; hence, they bring waste (inefficiencies) to your process. however, does this mean all waste is redundant?. Understanding value added vs non value added supports organizations in their pursuit of lean operations and continuous improvement. properly differentiating between these categories through detailed process mapping and analysis allows for data driven waste reduction, lead time declines, and quality enhancement. Discover how to maximize efficiency in lean manufacturing by understanding the differences between value added, non value added, and waste process steps. this comprehensive guide explains key concepts of lean principles, offering insights into value creation and process improvement. Activities that do not add value to the end customer are considered waste. the waste can be broken into two categories: non valued added but necessary and non value & unnecessary. the later is pure waste and should be eliminated while the former should be reduced as much as possible. One of the fundamental principles of lean is the distinction between value added and non value added tasks. value added tasks directly contribute to meeting customer needs or improving the quality. Lean principle value add vs. non value add. for specialty contractors the field workforce represents most of their competitive advantage as well as their biggest source of variability.

Value Add And Non Value Add International Lean Six Sigma Institute Discover how to maximize efficiency in lean manufacturing by understanding the differences between value added, non value added, and waste process steps. this comprehensive guide explains key concepts of lean principles, offering insights into value creation and process improvement. Activities that do not add value to the end customer are considered waste. the waste can be broken into two categories: non valued added but necessary and non value & unnecessary. the later is pure waste and should be eliminated while the former should be reduced as much as possible. One of the fundamental principles of lean is the distinction between value added and non value added tasks. value added tasks directly contribute to meeting customer needs or improving the quality. Lean principle value add vs. non value add. for specialty contractors the field workforce represents most of their competitive advantage as well as their biggest source of variability.

Guide Non Value Add Analysis Learn Lean Sigma One of the fundamental principles of lean is the distinction between value added and non value added tasks. value added tasks directly contribute to meeting customer needs or improving the quality. Lean principle value add vs. non value add. for specialty contractors the field workforce represents most of their competitive advantage as well as their biggest source of variability.

Comments are closed.