Lean Vs Six Sigma 7 Types Of Waste Timwood In 3 Mins

Timwood 7 Wastes Lean Six Sigma Timwood Sticker Teepublic In this video, explained about lean concepts and six sigma concepts*lean 7 types of waste (timwood) transport inventory motion waiting over production. Timwoods represents 8 forms of waste in processes. learn what they are and how to reduce them to achieve efficiency and effectiveness.

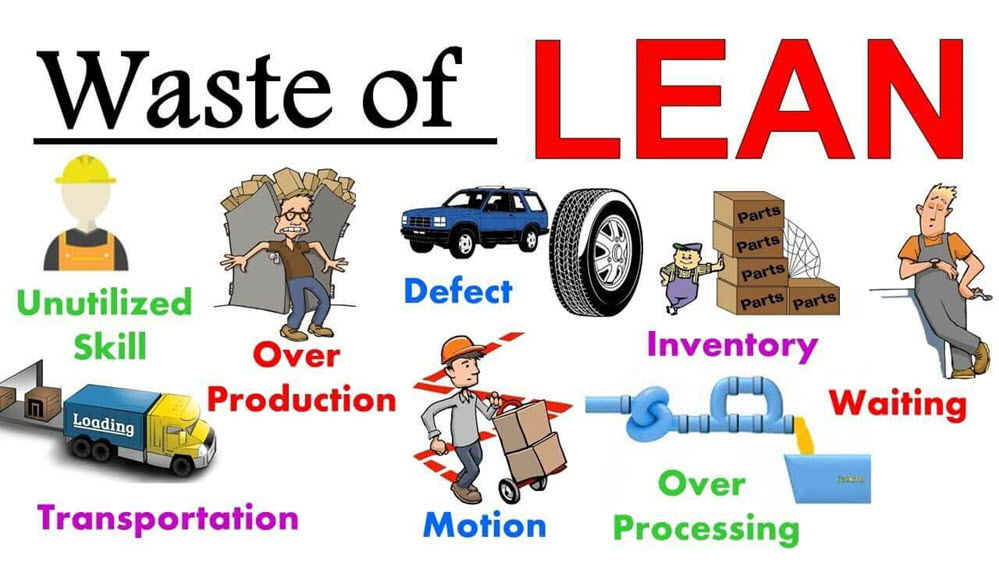

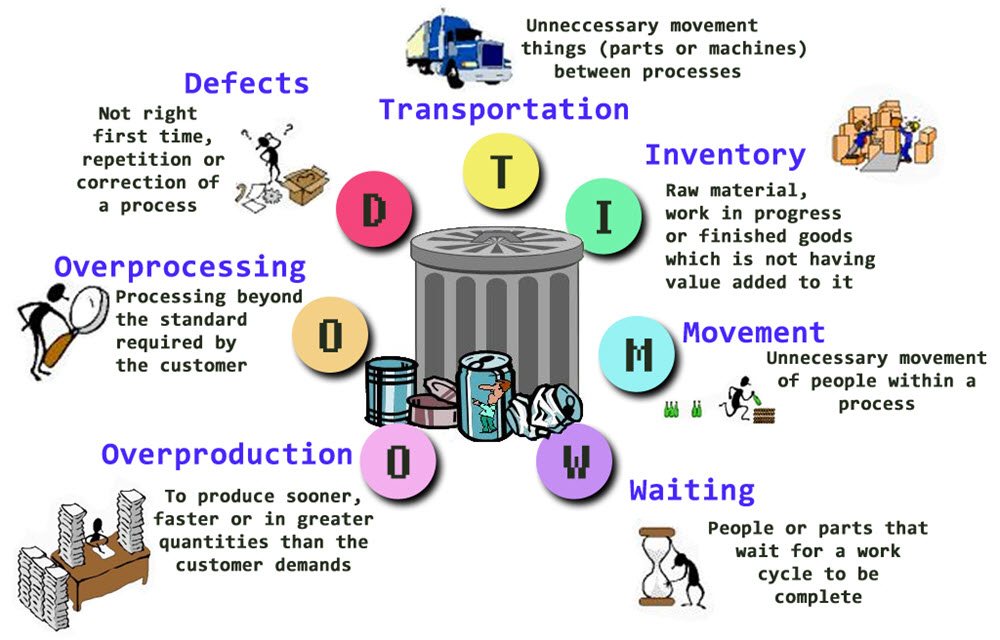

Pdf Lean Six Sigma In Research Lean Methods Remove Non Value Added Waste Timwood Timwood analysis is helpful for organizations in identifying and eliminating lean six sigma waste in business processes. in this blog, we will understand the fundamentals, principles and importance of timwood analysis along with effective strategies for it. The seven wastes of lean, remembered by the acronym timwood, represent different types of inefficiencies in production and business processes. let’s explore each type of waste, provide examples, and suggest strategies to eliminate them. Each letter in timwoods represents a type of waste (they are also known as the eight wastes of lean six sigma). keep on reading to find out what each of those letters means. Explore eight types of waste in lean manufacturing: transportation, inventory, motion, waiting, overproduction, over processing, defects, and underutilization of skills.

What Is Timwood Waste Within Lean Latest Quality Each letter in timwoods represents a type of waste (they are also known as the eight wastes of lean six sigma). keep on reading to find out what each of those letters means. Explore eight types of waste in lean manufacturing: transportation, inventory, motion, waiting, overproduction, over processing, defects, and underutilization of skills. Learn the 7 wastes of lean, the tim wood acronym, and how they affect your company's bottom line and the actions to counter these wastes. Wasteful practices can cost a company a lot of money. there are many methods to help a company remove waste. this lesson centers around 7 important places to start using lean six sigma. The acronym timwood represents the seven types of waste that organizations must identify and eliminate to streamline operations. In lean manufacturing, timwood represents seven types of waste that should be minimized or eliminated to improve efficiency and productivity. here are each of the timwood wastes with examples:.

Timwood Lean Refers To The 7 Waste Of Lean Latest Quality Learn the 7 wastes of lean, the tim wood acronym, and how they affect your company's bottom line and the actions to counter these wastes. Wasteful practices can cost a company a lot of money. there are many methods to help a company remove waste. this lesson centers around 7 important places to start using lean six sigma. The acronym timwood represents the seven types of waste that organizations must identify and eliminate to streamline operations. In lean manufacturing, timwood represents seven types of waste that should be minimized or eliminated to improve efficiency and productivity. here are each of the timwood wastes with examples:.

Comments are closed.