Lifter Calculation For Plastic Mold Design %d0%bf%d1%91%d1%9fautomobile Injection Mold

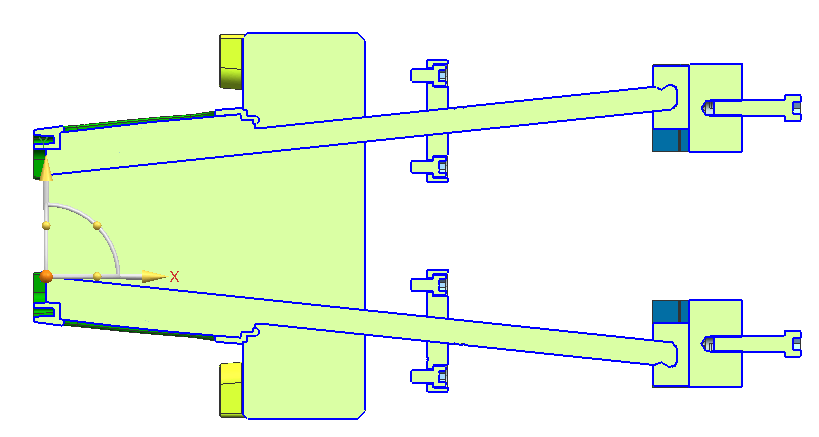

Lifter Design For Plastic Injection Mold Plastic Injection Molding And Mold Maker Manufacturing In this tutorials we'll discuss lifter design calculation for plastic injection mold design. here we'll calculate lifter angle & strokes. 1) all mechanical slide design standards relative to shut off, molding surfaces, and cooling will apply to the hydraulic slide designs. 2) parker series 2 h hydraulic cylinders will be used.

3d Accuracy Llc Lifter Mold Designs Learn about the mold lifter in injection mold, from design principles to key components, enhancing part ejection and manufacturing efficiency. This blog will provide a detailed overview of key guidelines for designing lifters in injection molds, including lifter structure types, working principles, and design considerations. Dive deep into the technicalities of injection mold lifter design, including step by step processes, design considerations, and practical tips for efficient mold making. Master the process of injection mold lifter design by detailed 9 steps. enhance your understanding to ensure successful mold operations.

Guidelines For Injection Mold Lifter Design Alpine Mold Dive deep into the technicalities of injection mold lifter design, including step by step processes, design considerations, and practical tips for efficient mold making. Master the process of injection mold lifter design by detailed 9 steps. enhance your understanding to ensure successful mold operations. The lifter is mainly used to form the internal undercuts of an injection molded plastic part, and at the same time it also offers ejection function. considerations in lifter design include selecting abrasion resistant and durable materials to withstand pressures and ensure operational efficiency. Designing injection molding lifters is a complex process that requires careful planning and execution. in this section, we'll walk you through the step by step process of designing lifters that are efficient, reliable, and built to last. This document discusses lifter calculation and injection molding. it provides values for the movement of the lifter in millimeters, the ejection stroke in millimeters, and the suitable angle in degrees for the lifter calculation of an injection mold.

Guidelines For Injection Mold Lifter Design Alpine Mold The lifter is mainly used to form the internal undercuts of an injection molded plastic part, and at the same time it also offers ejection function. considerations in lifter design include selecting abrasion resistant and durable materials to withstand pressures and ensure operational efficiency. Designing injection molding lifters is a complex process that requires careful planning and execution. in this section, we'll walk you through the step by step process of designing lifters that are efficient, reliable, and built to last. This document discusses lifter calculation and injection molding. it provides values for the movement of the lifter in millimeters, the ejection stroke in millimeters, and the suitable angle in degrees for the lifter calculation of an injection mold.

Comments are closed.