Revolutionize Quality Control With Ai Defect Detection Computer

Ai Defect Detection Types Advantages How To Implement It Ai powered quality control is revolutionizing the manufacturing sector. using machine learning and computer vision, ai systems can automatically detect defects with greater speed and precision than human inspectors or traditional systems. Azure ai and computer vision revolutionize quality control in manufacturing by providing real time, scalable, and highly accurate defect detection. by integrating custom vision, machine learning, and iot edge, manufacturers can significantly enhance efficiency, reduce defects, and cut costs.

From Defect Detection To Perfection How Ai Transforms Quality Control Way2unknown Ai visual inspection replaces outdated inspection methods with intelligent, automated systems for defect detection. by integrating computer vision and deep learning models, manufacturers can now detect defects in real time, enhance quality control, and drastically reduce production losses. Discover how ai enhances quality control in manufacturing with real time monitoring, predictive maintenance, and automated defect detection for better efficiency. Ai systems can process and analyze product images or sensor data in milliseconds, far faster than human inspectors. this enables real time defect detection and immediate corrective actions, reducing bottlenecks and speeding up production cycles. 5. what types of ai technologies are commonly used in manufacturing quality control?. Ai powered quality control systems offer unprecedented speed, accuracy, and scalability. unlike human inspectors, ai maintains constant vigilance, analyzing hundreds of components per minute with superior precision.

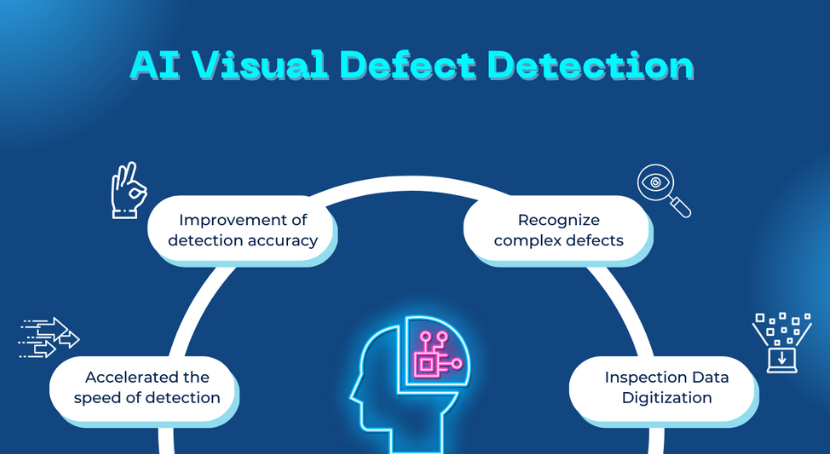

Ai In Quality Control And Defect Detection Ai systems can process and analyze product images or sensor data in milliseconds, far faster than human inspectors. this enables real time defect detection and immediate corrective actions, reducing bottlenecks and speeding up production cycles. 5. what types of ai technologies are commonly used in manufacturing quality control?. Ai powered quality control systems offer unprecedented speed, accuracy, and scalability. unlike human inspectors, ai maintains constant vigilance, analyzing hundreds of components per minute with superior precision. How does edge ai improve quality control in manufacturing? edge ai enables real time detection and correction of defects during production. by running ai models directly on devices like cameras and sensors, manufacturers can identify anomalies immediately, reduce waste, and ensure consistent quality, without latency from cloud processing. Automated defect detection for manufacturing is not just a competitive advantage—it’s fast becoming a necessity. with benefits like improved quality, reduced costs, and faster feedback loops, ai powered vision inspection is revolutionizing how factories operate. Ai defect detection refers to the use of artificial intelligence (ai) and computer vision to automatically identify defects in products during the manufacturing process. traditionally, defect detection relied on manual inspection by human operators or basic automation tools. This comprehensive overview examines how ai driven inspection systems are revolutionizing manufacturing quality control, from their technical foundations to their practical implementation across diverse industrial applications.

Ai Defect Detection Solution How does edge ai improve quality control in manufacturing? edge ai enables real time detection and correction of defects during production. by running ai models directly on devices like cameras and sensors, manufacturers can identify anomalies immediately, reduce waste, and ensure consistent quality, without latency from cloud processing. Automated defect detection for manufacturing is not just a competitive advantage—it’s fast becoming a necessity. with benefits like improved quality, reduced costs, and faster feedback loops, ai powered vision inspection is revolutionizing how factories operate. Ai defect detection refers to the use of artificial intelligence (ai) and computer vision to automatically identify defects in products during the manufacturing process. traditionally, defect detection relied on manual inspection by human operators or basic automation tools. This comprehensive overview examines how ai driven inspection systems are revolutionizing manufacturing quality control, from their technical foundations to their practical implementation across diverse industrial applications.

The Machines Are Watching Quality Control And Defect Detection With Ai Manufacturing Automation Ai defect detection refers to the use of artificial intelligence (ai) and computer vision to automatically identify defects in products during the manufacturing process. traditionally, defect detection relied on manual inspection by human operators or basic automation tools. This comprehensive overview examines how ai driven inspection systems are revolutionizing manufacturing quality control, from their technical foundations to their practical implementation across diverse industrial applications.

Comments are closed.