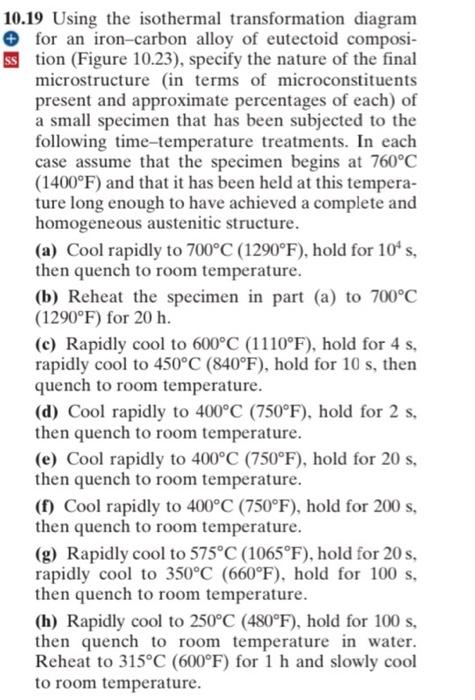

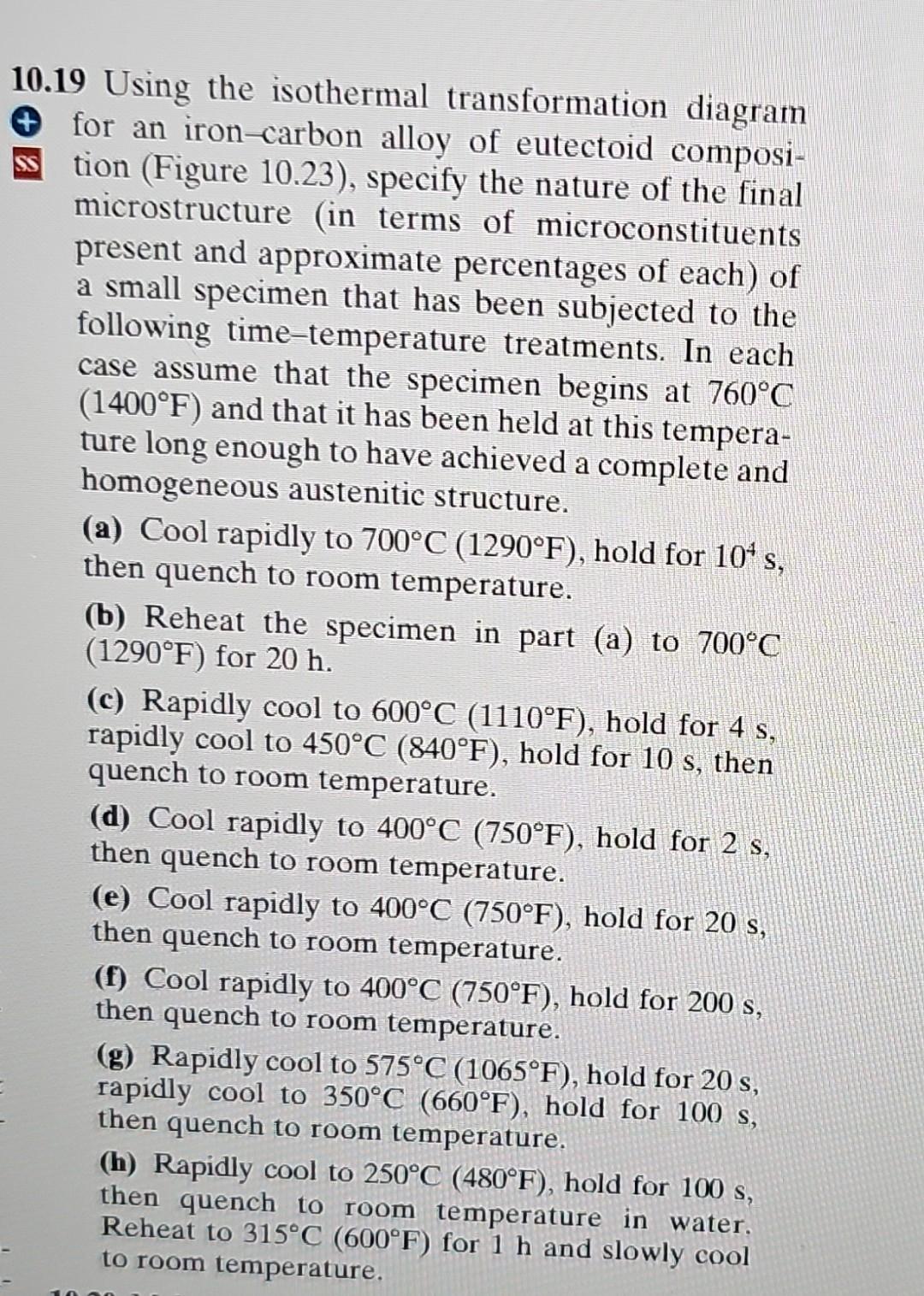

Solved 19 Using The Isothermal Transformation Diagram Fo

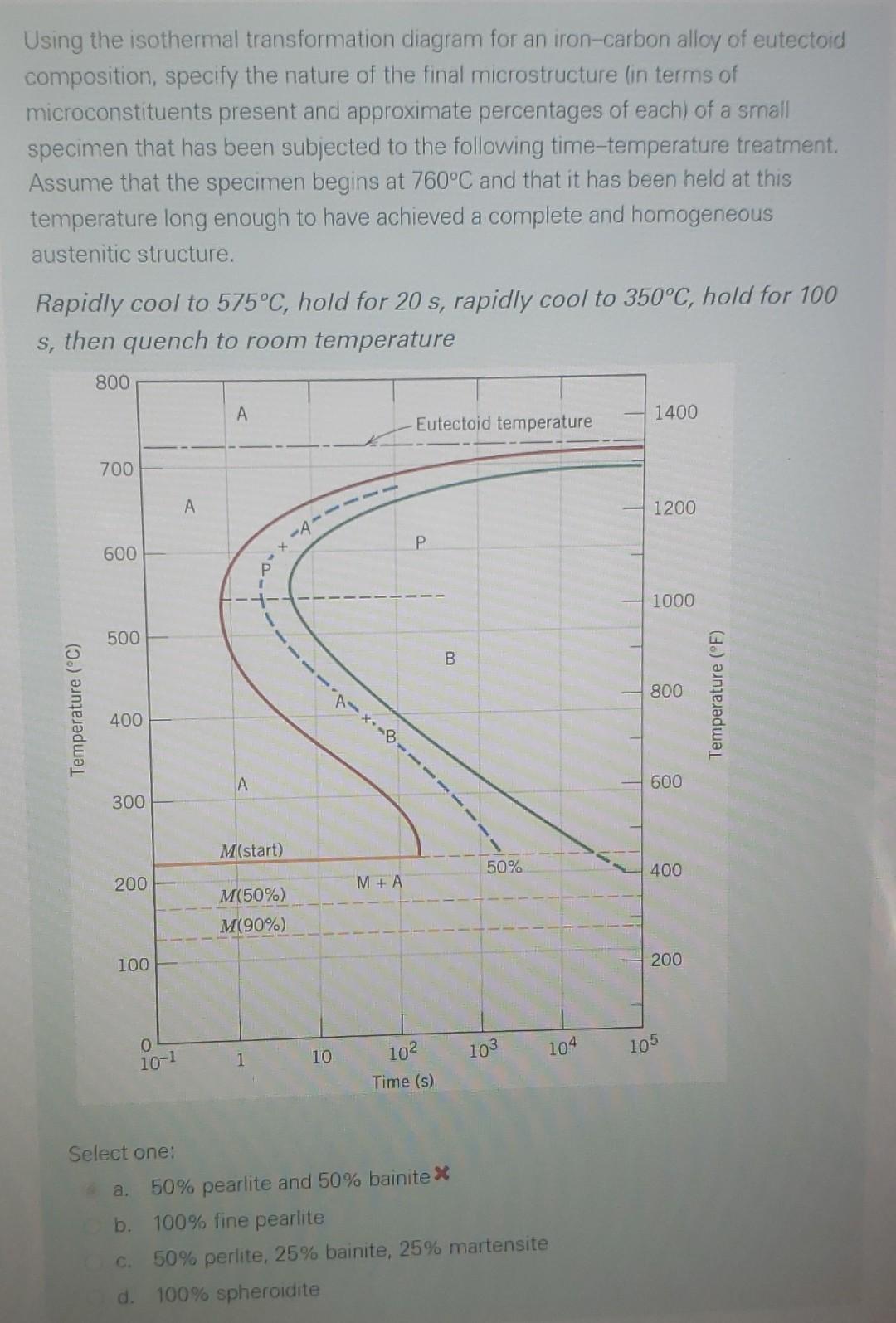

Solved 19 Using The Isothermal Transformation Diagram Fo Our expert help has broken down your problem into an easy to learn solution you can count on. • the ttt diagram shows temperature versus time for an iron carbon alloy, illustrating transformation into various microstructures like pearlite (p), bainite (b), and martensite (m). • the curves represent start and end points for pearlite, bainite, and martensite transformations.

Solved 19 Using The Isothermal Transformation Diagram For An Chegg 10.18 below is shown an isothermal transformation diagram for a 0.45 wt% c iron carbon alloy, with time temperature paths that will produce (a) 42% proeutectoid ferrite and 58% coarse pearlite; (b) 50% fine pearlite and 50% bainite; (c) 100% martensite; and (d) 50% martensite and 50% austenite. What is the t t t diagram? t t t diagram is also called isothermal transformation diagram [temperature time –transformation]. it is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. 2 phase transformation solutions free download as pdf file (.pdf) or read online for free. 10.21 using the isothermal transformation diagram for a 0.45 wt% c steel alloy (figure 10.40), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time temperature treatments.

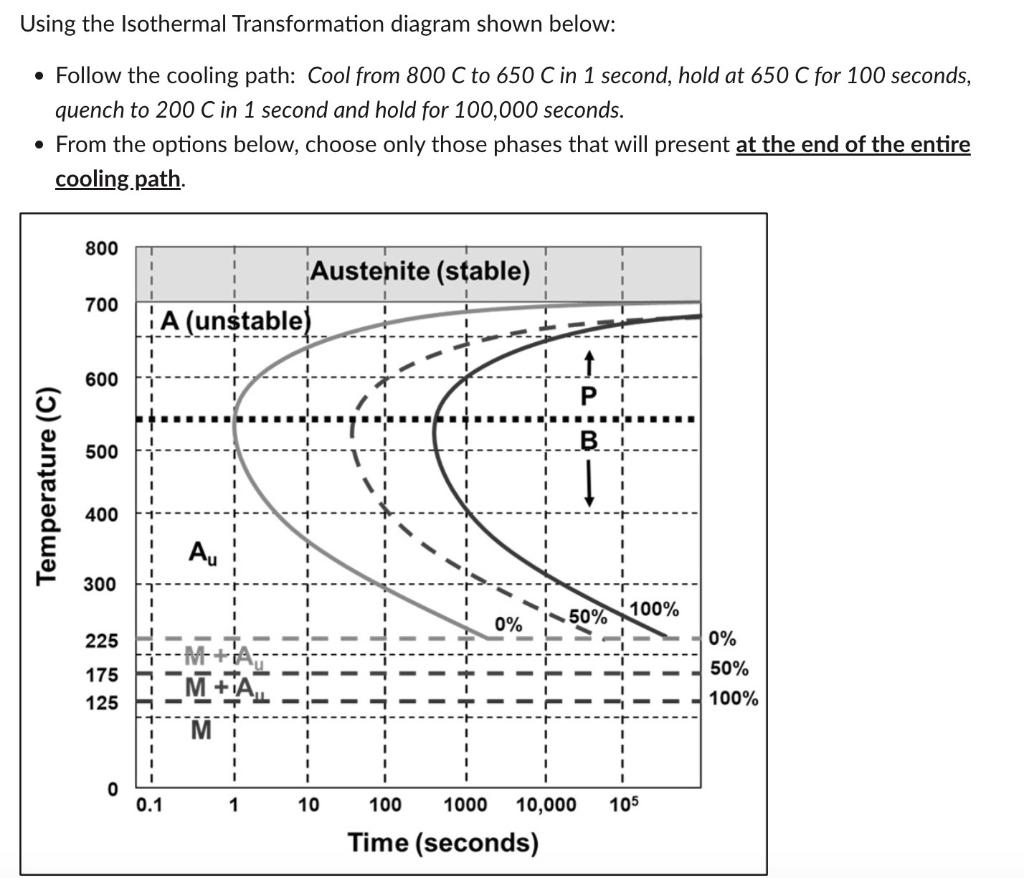

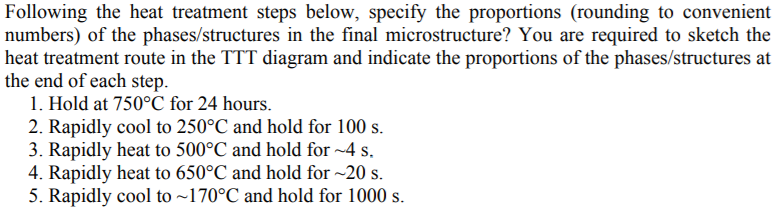

Solved Using The Isothermal Transformation Diagram Shown Chegg 2 phase transformation solutions free download as pdf file (.pdf) or read online for free. 10.21 using the isothermal transformation diagram for a 0.45 wt% c steel alloy (figure 10.40), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time temperature treatments. To determine the final microstructure of the iron carbon alloy of eutectoid composition after each time temperature treatment, we will refer to the isothermal transformation diagram (figure 10.22) for the alloy. Our expert help has broken down your problem into an easy to learn solution you can count on. question: 19. [6 pts] use the isothermal transformation diagram shown below to describe how a) pearlite b) 50% bainite, 50% martensite can be developed. Q10.20 using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments. Solution this problem asks us to determine the nature of the final microstructure of an iron carbon alloy of eutectoid composition, that has been subjected to various isothermal heat treatments. figure 10.22 is used in these determinations.

Solved Using The Isothermal Transformation Diagram For A Chegg To determine the final microstructure of the iron carbon alloy of eutectoid composition after each time temperature treatment, we will refer to the isothermal transformation diagram (figure 10.22) for the alloy. Our expert help has broken down your problem into an easy to learn solution you can count on. question: 19. [6 pts] use the isothermal transformation diagram shown below to describe how a) pearlite b) 50% bainite, 50% martensite can be developed. Q10.20 using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments. Solution this problem asks us to determine the nature of the final microstructure of an iron carbon alloy of eutectoid composition, that has been subjected to various isothermal heat treatments. figure 10.22 is used in these determinations.

Solved Using The Isothermal Transformation Diagram For An Chegg Q10.20 using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments. Solution this problem asks us to determine the nature of the final microstructure of an iron carbon alloy of eutectoid composition, that has been subjected to various isothermal heat treatments. figure 10.22 is used in these determinations.

Solved Using The Isothermal Transformation Diagram For An Chegg

Comments are closed.