Solved Final Microstructures Estimated By Ttt Curve Using Chegg

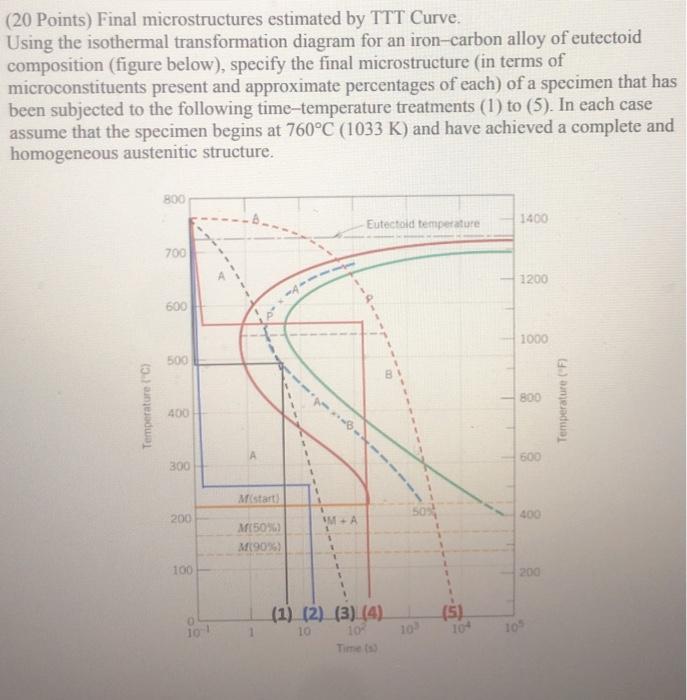

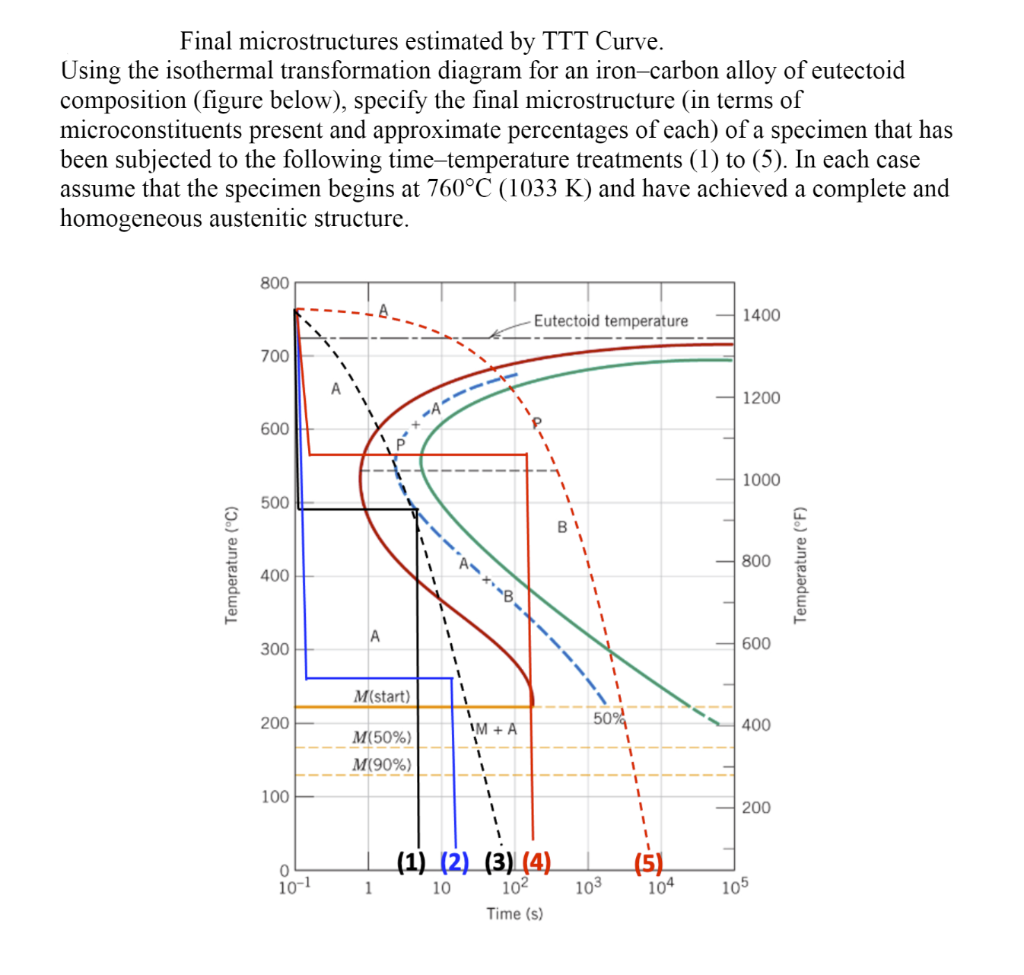

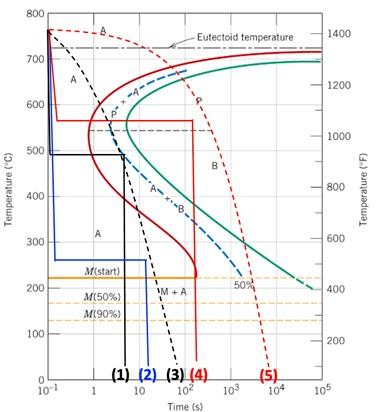

Solved 20 Points Final Microstructures Estimated By Ttt Chegg Final microstructures estimated by ttt curve. using the isothermal transformation diagram for an iron carbon alloy of eutectoid composition (figure below), specify the final microstructure (in terms of microconstituents present and approximate percentages of each) of a specimen that has been subjected to the following time temperature. Schematic ttt diagrams for eutectoid, hypoeutectoid and hyper eutectoid steel are shown in fig.4, figs. 7(a) (b) and all of them together along with schematic fe fe.

Solved Final Microstructures Estimated By Ttt Curve Using Chegg It is used to determine when transformations begin and end for an isothermal (constant temperature) heat treatment of a previously austenitized alloy. when austenite is cooled slowly to a temperature below lct (lower critical temperature), the structure that is formed is pearlite. Final microstructures estimated by ttt curve. using the isothermal transformation diagram for an iron—carbon. Final microstructures estimated by ttt curve using the isothermal transformation diagram for an iron carbon alloy of eutectoid composition (figure below), specify the final microstructure (in terms of microconstituents present and approximate percentages of each) of a specimen that has been subjected to the following time temperature treatments. This diagram is also called as c curve isothermal (decomposition of austenite) diagram and bain’s curve. the effect of time temperature on the microstructure changes of steel can be shown by the ttt diagram.

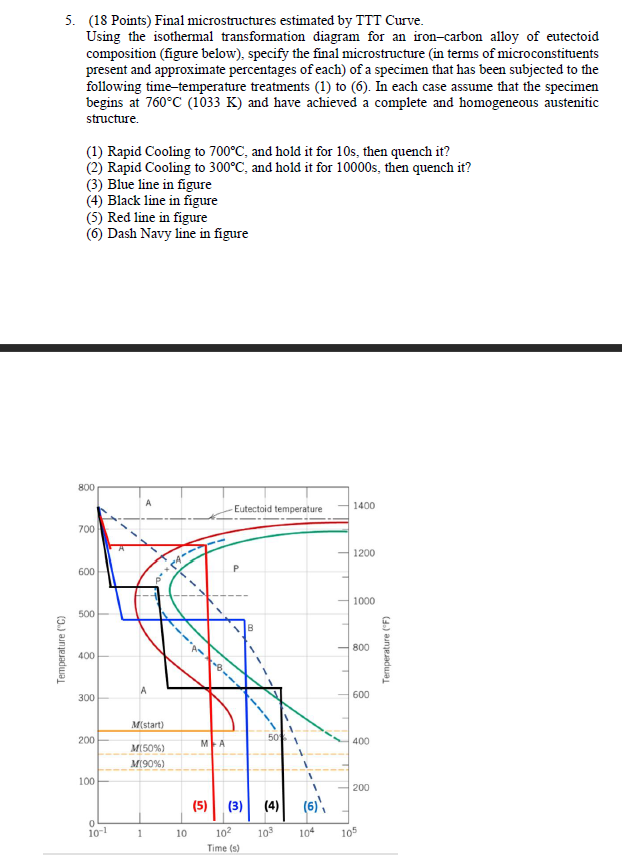

5 18 Points Final Microstructures Estimated By Ttt Chegg Final microstructures estimated by ttt curve using the isothermal transformation diagram for an iron carbon alloy of eutectoid composition (figure below), specify the final microstructure (in terms of microconstituents present and approximate percentages of each) of a specimen that has been subjected to the following time temperature treatments. This diagram is also called as c curve isothermal (decomposition of austenite) diagram and bain’s curve. the effect of time temperature on the microstructure changes of steel can be shown by the ttt diagram. Search our library of 100m curated solutions that break down your toughest questions. For a better understanding of heat treatments of steel, a ttt diagram has been a requirement. using the ttt diagram the phase transformation sequence for microstructures has been estimated in terms of temperature and time. Using the isothermal transformation diagram for a 0.45 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time temperature treatments. Given below is a typical ttt diagram. click on a temperature below to show how the microstructure develops relative to the ttt diagram.

Solved Final Microstructures Estimated By Ttt Curve Using Chegg Search our library of 100m curated solutions that break down your toughest questions. For a better understanding of heat treatments of steel, a ttt diagram has been a requirement. using the ttt diagram the phase transformation sequence for microstructures has been estimated in terms of temperature and time. Using the isothermal transformation diagram for a 0.45 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time temperature treatments. Given below is a typical ttt diagram. click on a temperature below to show how the microstructure develops relative to the ttt diagram.

Comments are closed.