Solved Using The Isothermal Transformation Diagram For An Chegg

Solved 500 Isothermal Transformation Diagram Using The Chegg Using the isothermal transformation diagram given in figure 2 for a specific material composition to answer the following (this is not an fe−c steel!). note: assume that you begin with a single phase sample of α at 790c. Below is shown the isothermal transformation diagram for a eutectoid iron carbon alloy, with time temperature paths that will yield (a) 100% fine pearlite; (b) 100% tempered martensite; and (c) 50% coarse pearlite, 25% bainite, and 25% martensite.

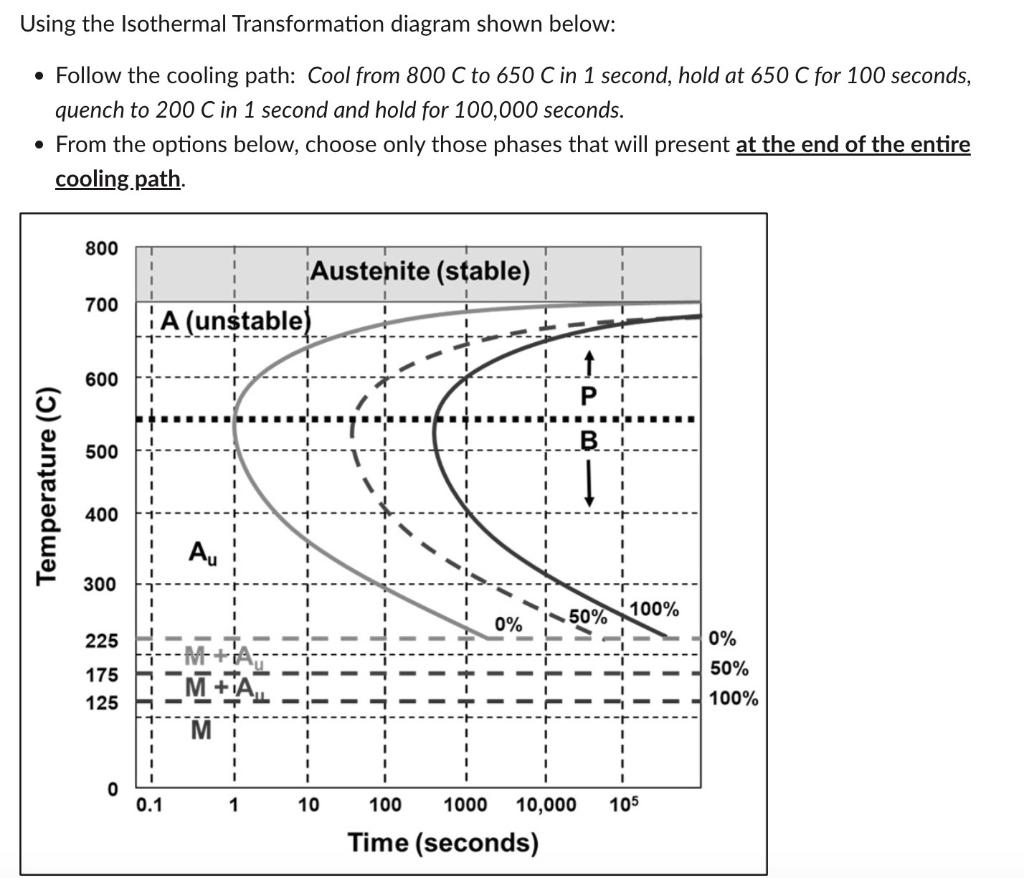

Solved Using The Isothermal Transformation Diagram Shown Chegg Superheating and supercooling correspond, respectively, to heating or cooling above or below a phase transition temperature without the occurrence of the transformation. the critical radius of a nuclei is smaller when the supercooling is larger. Video answer: we are to solve this question. we have that the 100 % of benite is formed. when specie man is cooled, spaceman is cooled rapidly from 3 .50 degrees celsius to 760 degrees celsius and held at. 10 days to the per 3 second and cold to…. Solved below is shown the isothermal transformation diagram chemistry expert. first, identify the microconstituent (s) for the heat treatment labeled in part (a) on the isothermal transformation diagram. What is the t t t diagram? t t t diagram is also called isothermal transformation diagram [temperature time –transformation]. it is a plot of temperature versus the logarithm of time for a steel alloy of definite composition.

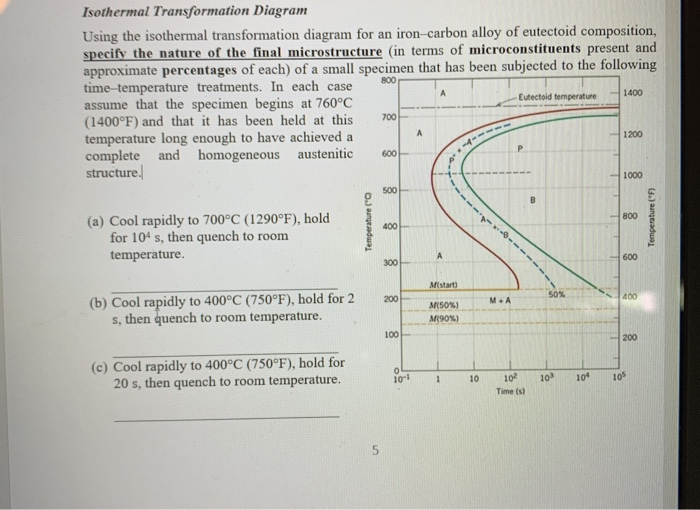

Solved Using The Isothermal Transformation Diagram For A Chegg Solved below is shown the isothermal transformation diagram chemistry expert. first, identify the microconstituent (s) for the heat treatment labeled in part (a) on the isothermal transformation diagram. What is the t t t diagram? t t t diagram is also called isothermal transformation diagram [temperature time –transformation]. it is a plot of temperature versus the logarithm of time for a steel alloy of definite composition. The document provides solutions to problems involving interpreting an isothermal transformation diagram for an iron carbon alloy of eutectoid composition. in problem 1, it is determined that for 50% completion of the austenite to pearlite reaction it will take 6 seconds, and for 100% completion it will take 9 seconds. Using the isothermal transformation diagram for an iron carbon alloy of eutectoid composition shown below, specify the nature of the final microstructure (in terms of microconstituents present and approximate percentages of each) of a small specimen that has been subjected to the following time temperature treatments. in each case assume that the. The formation of pearlite can be predicted using ttt diagrams, where it typically forms at temperatures between 550°c and 650°c. understanding pearlite formation is key to manipulating the toughness of steel during manufacturing processes. Study with quizlet and memorize flashcards containing terms like isothermal transformation diagram, curve, upper transformation temperature and more.

Comments are closed.