Solvedusing The Isothermal Transformation Diagram For A 1 1

Isothermal Transformation Diagram Alchetron The Free Social Encyclopedia Using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 10.39) determine the final microstructure in terms of just the microconstituents present) of a small specimen that has been subjected to the following time temperature treatments. About.

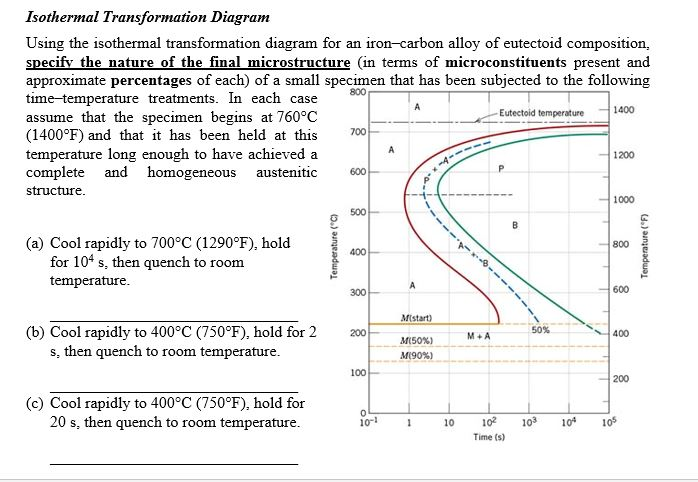

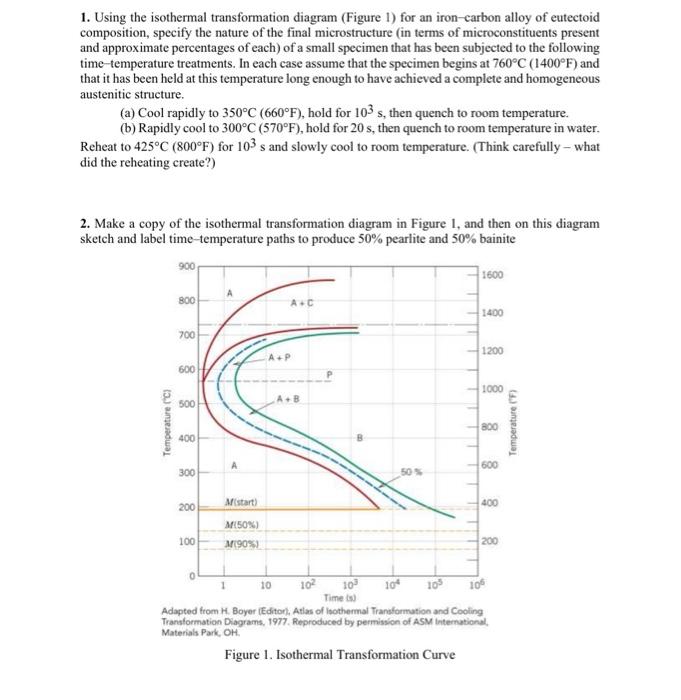

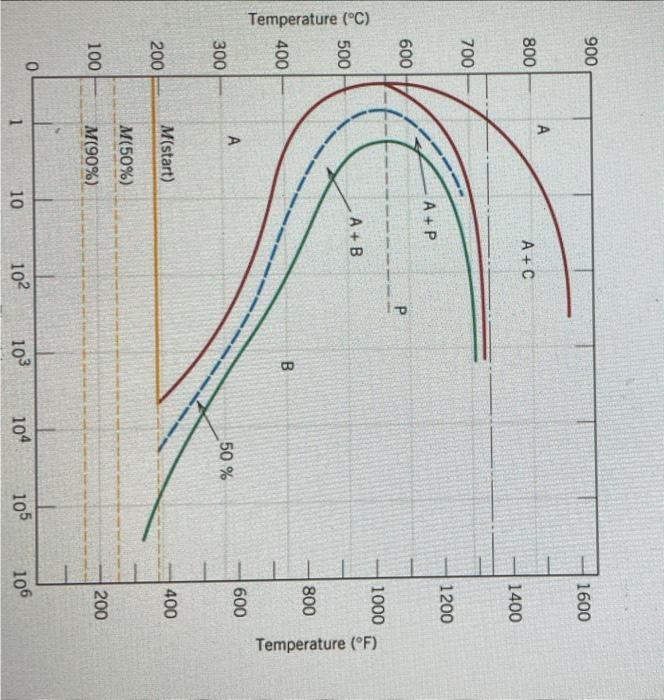

Solved Isothermal Transformation Diagram Using The Chegg Below is shown the isothermal transformation diagram for a eutectoid iron carbon alloy, with time temperature paths that will yield (a) 100% fine pearlite; (b) 100% tempered martensite; and (c) 50% coarse pearlite, 25% bainite, and 25% martensite. Using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 11.49), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments. Q10.20 using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments. Using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments.

Solved Question 1 A Draw The Isothermal Transformation Chegg Q10.20 using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments. Using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 10.39), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments. Ttt diagram of isothermal transformations of a hypoeutectoid carbon steel; showing the main components obtained when cooling the steel and its relation with the fe c phase diagram of carbon steels. austenite is slightly undercooled when quenched below eutectoid temperature. Using the isothermal transformation diagram for a 1.13 wt.% c steel alloy given below, determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time temperature treatment. Interpret the isothermal transformation diagram of 1.13 wt% c steel alloy (perry). and decide the microstructure of the material after cooling at various rates and holding for a duration at fixed temperature. Using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 11.50), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments.

Solved 1 Using The Isothermal Transformation Diagram Chegg Ttt diagram of isothermal transformations of a hypoeutectoid carbon steel; showing the main components obtained when cooling the steel and its relation with the fe c phase diagram of carbon steels. austenite is slightly undercooled when quenched below eutectoid temperature. Using the isothermal transformation diagram for a 1.13 wt.% c steel alloy given below, determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time temperature treatment. Interpret the isothermal transformation diagram of 1.13 wt% c steel alloy (perry). and decide the microstructure of the material after cooling at various rates and holding for a duration at fixed temperature. Using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 11.50), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments.

Solved Using The Isothermal Transformation Diagram For A Interpret the isothermal transformation diagram of 1.13 wt% c steel alloy (perry). and decide the microstructure of the material after cooling at various rates and holding for a duration at fixed temperature. Using the isothermal transformation diagram for a 1.13 wt% c steel alloy (figure 11.50), determine the final microstructure (in terms of just the microconstituents present) of a small specimen that has been subjected to the following time–temperature treatments.

Solved Using The Isothermal Transformation Diagram For A

Comments are closed.